Contact us

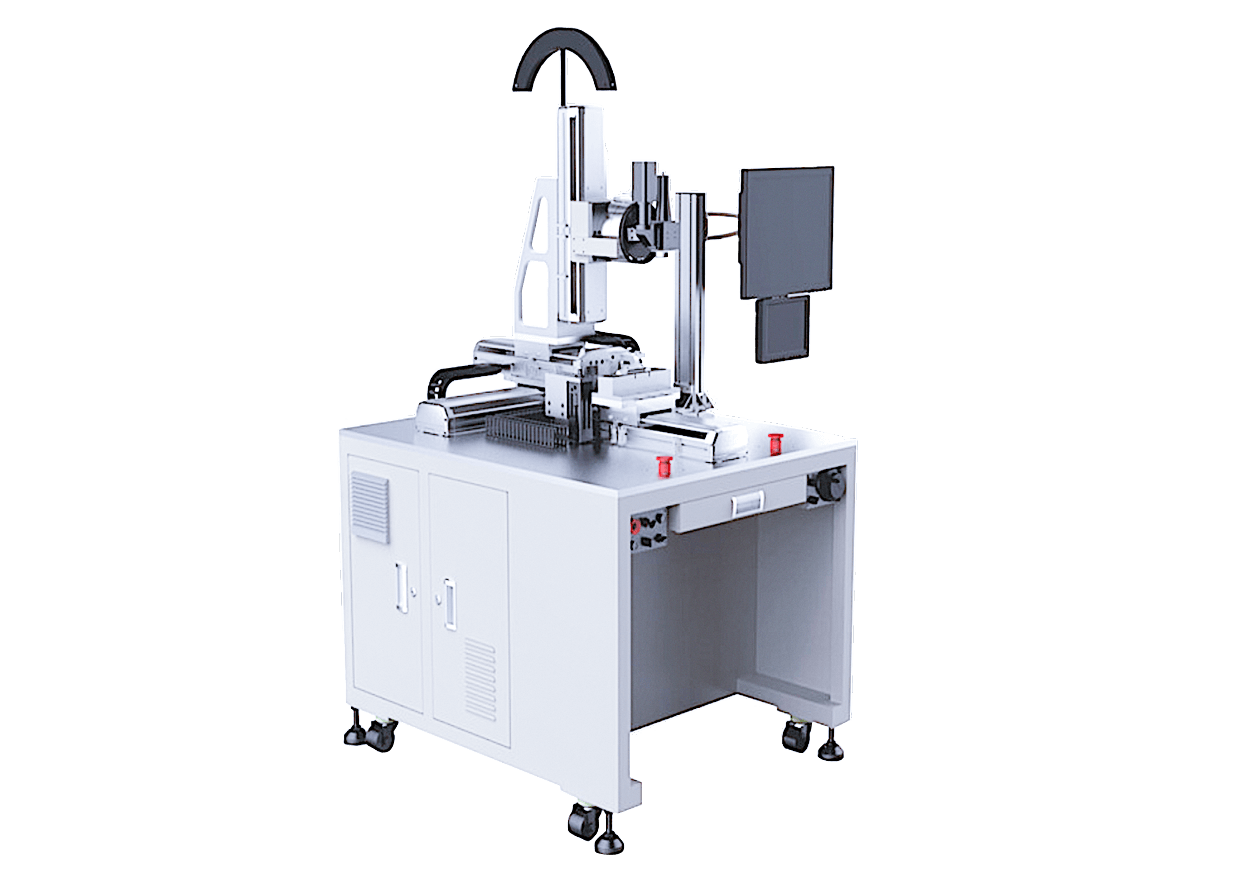

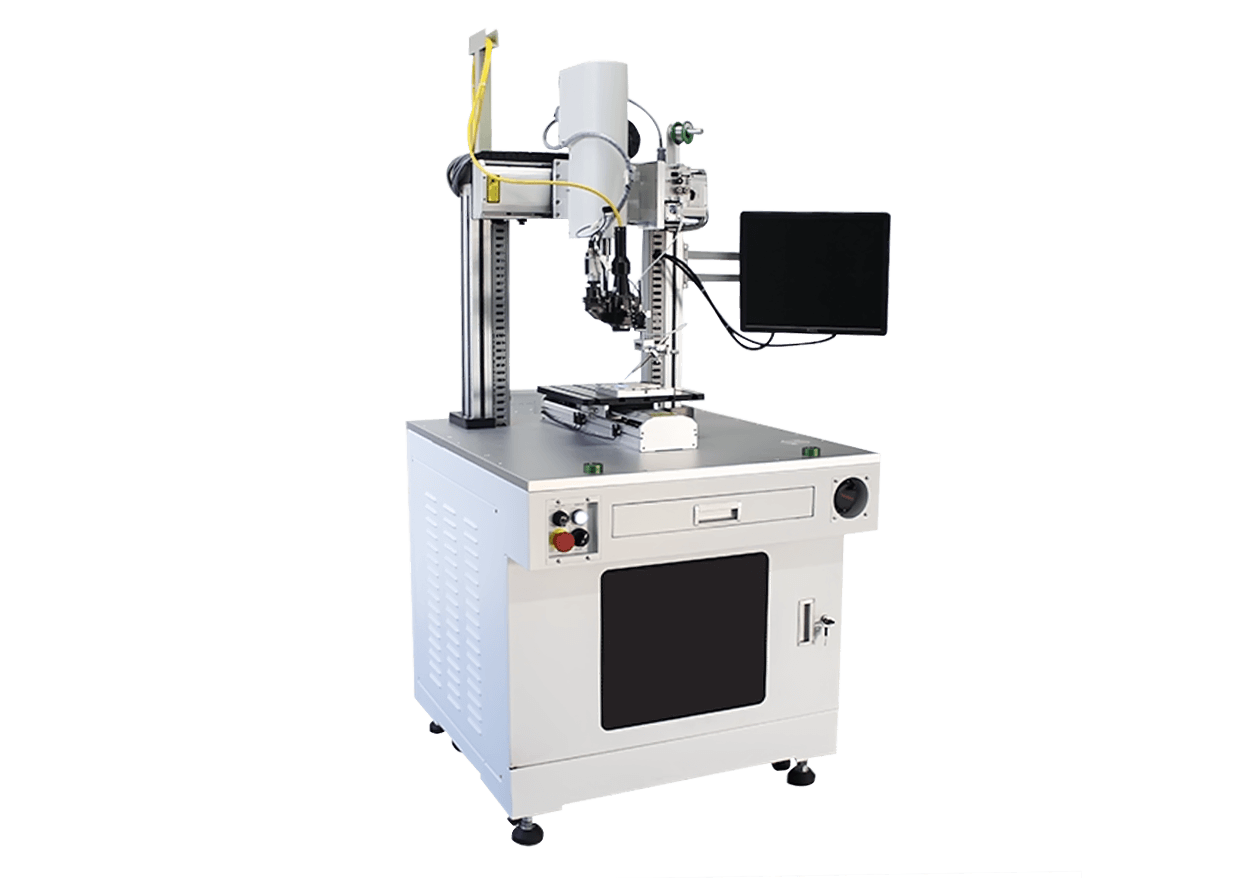

Fiber Laser Welding Machine - FP Series

Fiber laser welding machine for precise parts.

SFP fiber laser welder series is a new generation near-infrared semiconductor pumped fiber laser. With good beam quality, fiber transmission and high electro-optical conversion efficiency, it is mainly used for rapid welding thin materials.

The welding process is conduction welding, with the laser radiation heats the surface of the workpiece, and the surface heat is diffused to the inside through heat conduction.

By controlling parameters such as the width, energy, peak power and repetition frequency of the laser pulse, the workpiece can be melted to form a specific molten pool. It is widely applied to weld micro and small parts.

Contact us

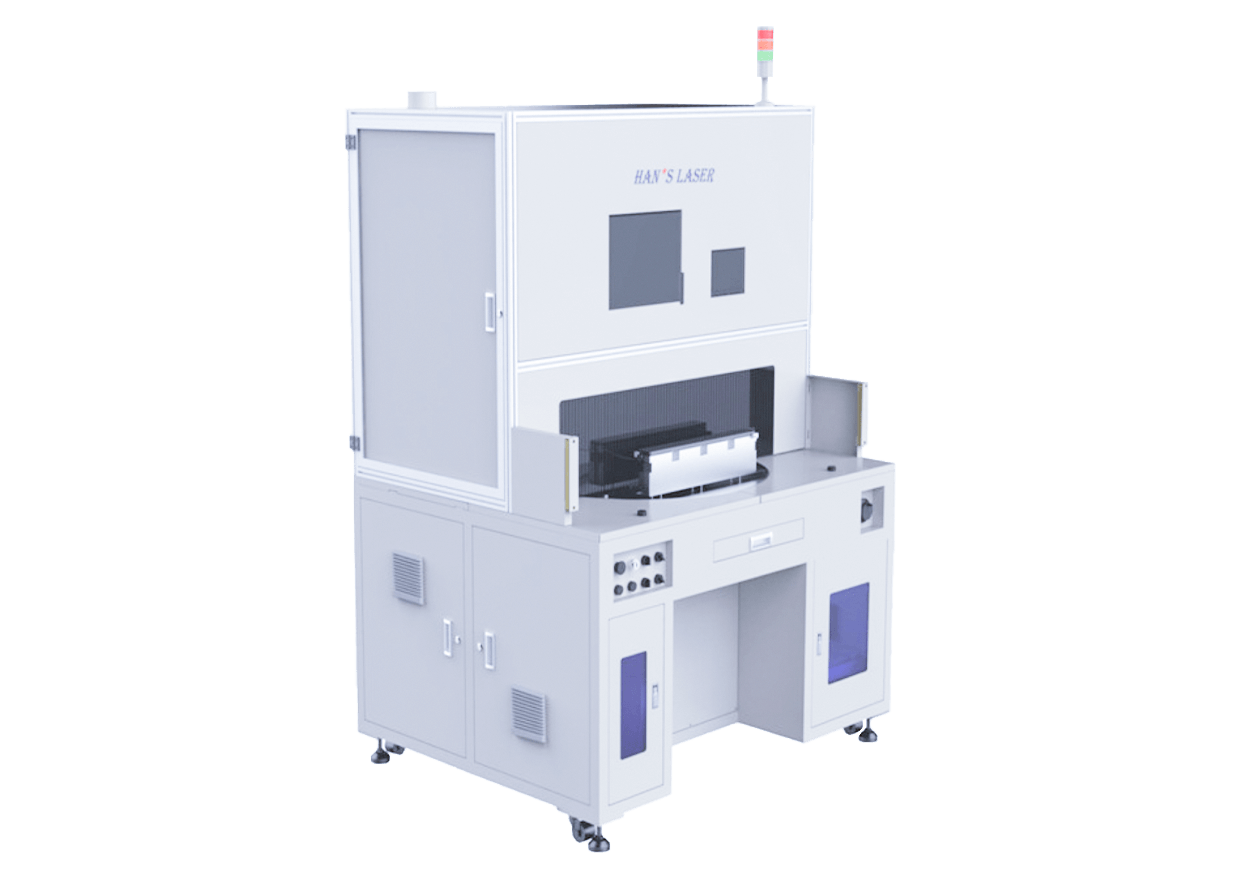

SFP fiber laser welder series is a new generation near-infrared semiconductor pumped fiber laser. With good beam quality, fiber transmission and high electro-optical conversion efficiency, it is mainly used for rapid welding thin materials.

The welding process is conduction welding, with the laser radiation heats the surface of the workpiece, and the surface heat is diffused to the inside through heat conduction.

By controlling parameters such as the width, energy, peak power and repetition frequency of the laser pulse, the workpiece can be melted to form a specific molten pool. It is widely applied to weld micro and small parts.

Features

- High aspect ratio, thin weld width, minimal heat-affected zone, zero deformation, and fast welding speed

- The weld is smooth and clean, with or without simple process after welding

- High electro-optical conversion efficiency, can be as high as 25%,

- Energy consumption is extremely low

- The optical device has a long lifespan and is maintenance-free

- Laser beam splitting system: One laser source can serve several welding stations

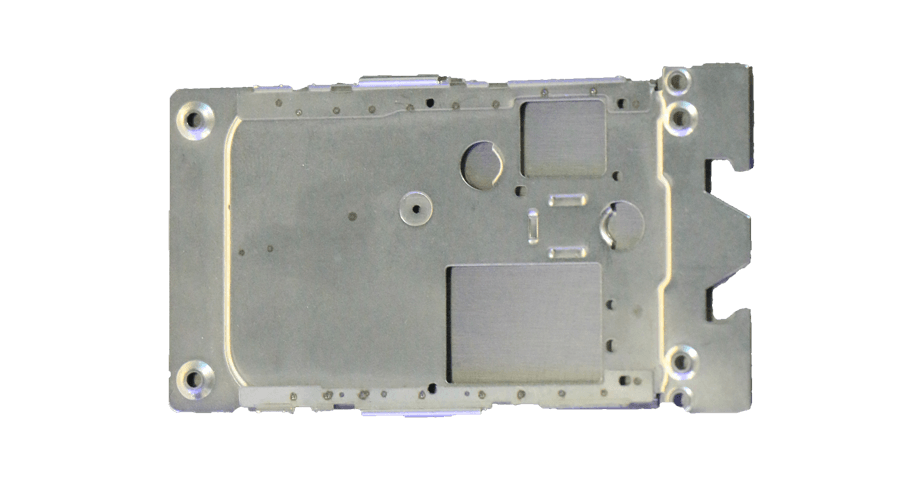

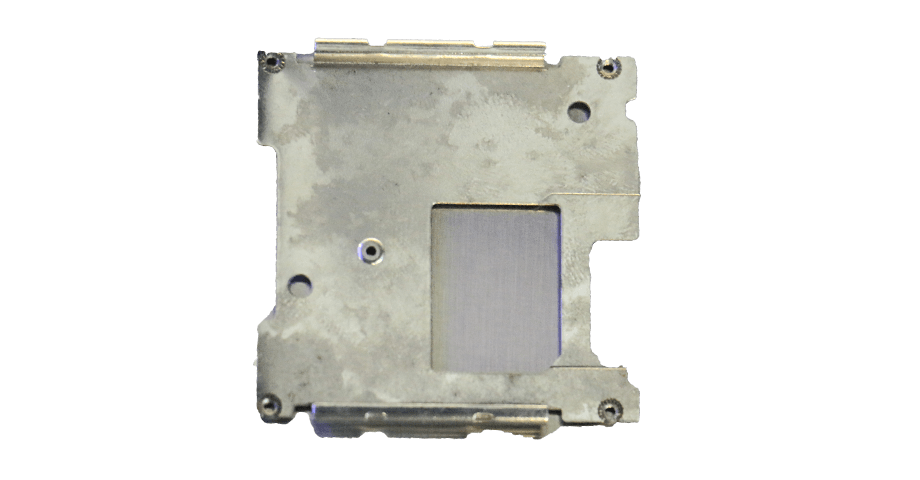

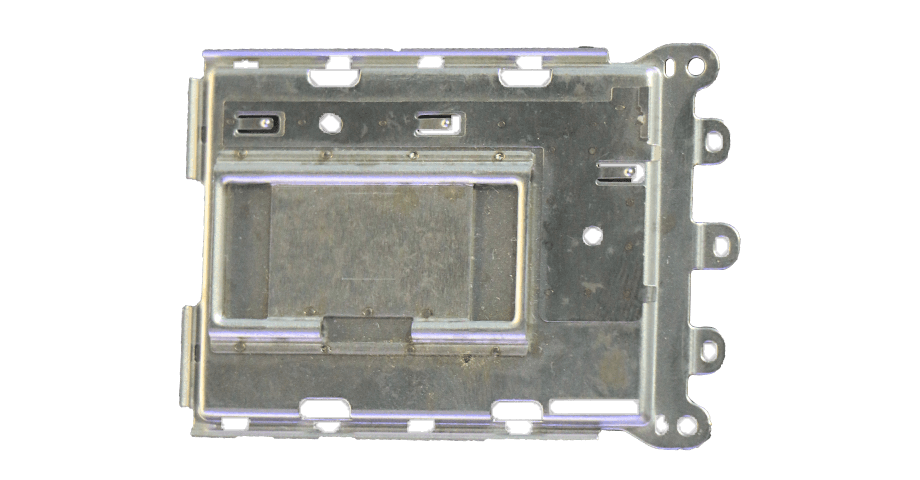

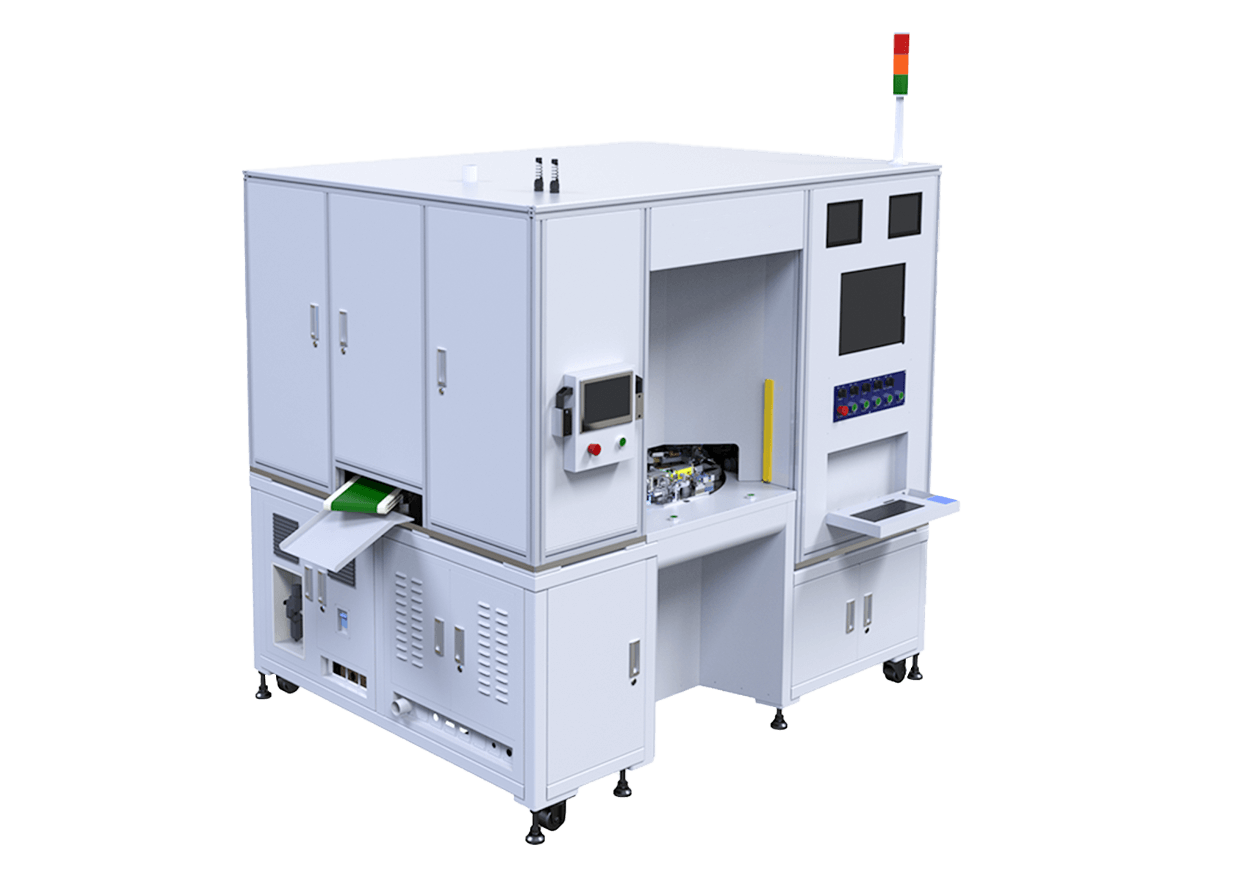

Application and Samples

- Battery welding, pipe welding, thin steel plate welding

- Electronic components, instrumentation, medical equipment, small metal parts welding

Material

- Stainless Steels, Carbon Steels

- Gold & Silver, Aluminum, Tool Steels

- Nickel Alloys, Brass & Copper, Titanium

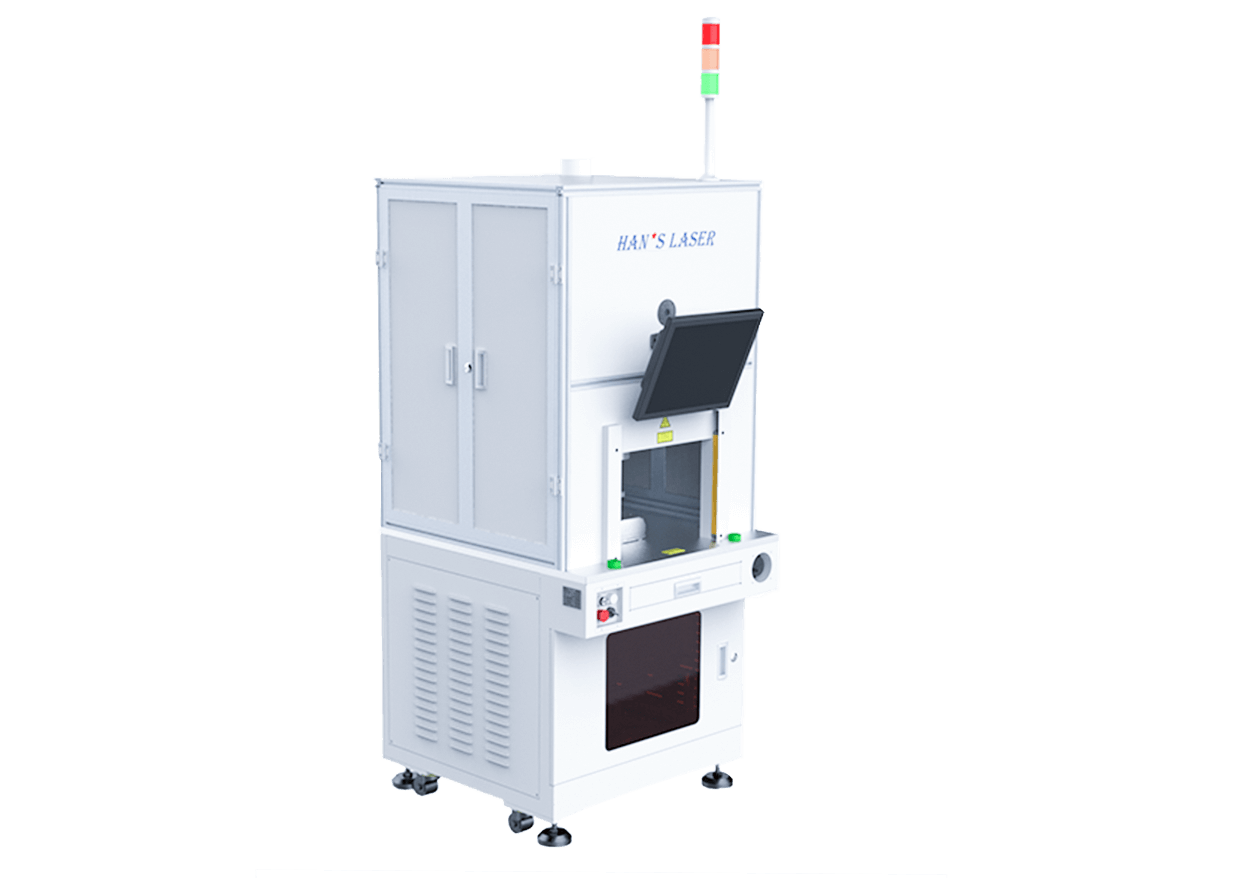

Technical Specs

| Laser Mode | SFP150 |

| Wavelength | 1070 nm |

| Work Mode | QW/CW |

| Maximum Average Power (W) | QW 150 W/ CW 250 W |

| Maximum Peak Power (kW) | 1.5 |

| Maximum Pulse Energy (J) | 15 |

| Pulse Width (ms) | 0.2~50 |

| Maximum Pulse Frequency (Hz) | 500 |

| Wave Form | 50 x 16 sections |

| Fiber Output | 1~4 |

| Maximum Beam Splitting Frequency (Hz) | 80 |

| Fiber Diameter (um) | 200 |

| Cooling System | Air-cooled |

| Power Input | 220±10%,50/60 Hz |

ABOUT HAN'S LASER CORPORATION

Han's Laser Corporation is a wholly-owned subsidiary of Han's Laser Technology Group, a global industrial laser technology leader.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

CLIENTS