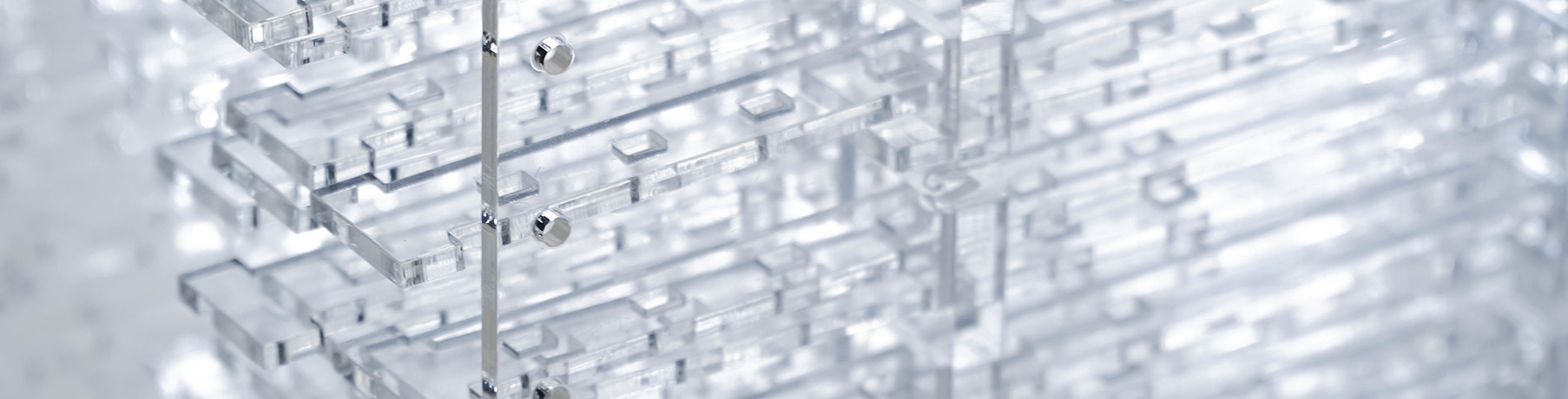

Laser welding plastic, the laser beam, after transmission through the upper-layer transparent material, will be absorbed by the lower layer. The laser energy, after being absorbed, will be transformed into heat. Since two layers of materials are forced together, the heat will be conducted to a transparent layer from the absorbing layer, making the two layers of materials melt and connected. At the same time, the internal pressure occurs because of the material's thermal expansion. The total effort of the internal and external pressure can make sure two layers are firmly welded. For the product, the lower-layer material does not absorb laser. An additive must be applied to the lower layer.

Almost all thermoplastics and thermoplastic elastomers can use laser welding technology. Commonly used welding materials are PP, PS, PC, ABS, polyamide, PMMA, POM, PET and PBT. However, some other engineering plastics, such as polyphenylene sulfide PPS and liquid crystal polymer, are not suitable for laser welding technology because of their low laser transmittance. Therefore, addictive is often added to the underlying material to absorb enough energy to meet the requirements of laser transmission welding.

Clear Material Laser Welding

Clear polymers required special infrared absorbers, which were expensive and difficult to apply. In transparent laser plastic welding, a higher wavelength laser is used, which interacts differently with the plastic than the typical 808nm or 980nm infrared lasers used in through-transmission welding. Some of the laser energy is still transmitted or passed through a transparent thermoplastic. Still, at this higher wavelength, some absorption is seen, volumetrically, enough volumetric absorption to heat and plasticize the polymer through the part.

When lasers pass through any medium, some of that laser energy will be absorbed by the lens's surfaces. In transparent plastic welding, there are four surfaces where absorption will increase: the upper surface, the two surfaces at the joint interface and the lower surface. Because the joint interface comprises two surfaces, most of the absorption in clear-to-clear welding occurs here, making it a perfect solution for joining transparent thermoplastics without absorber additives.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.