Contact us

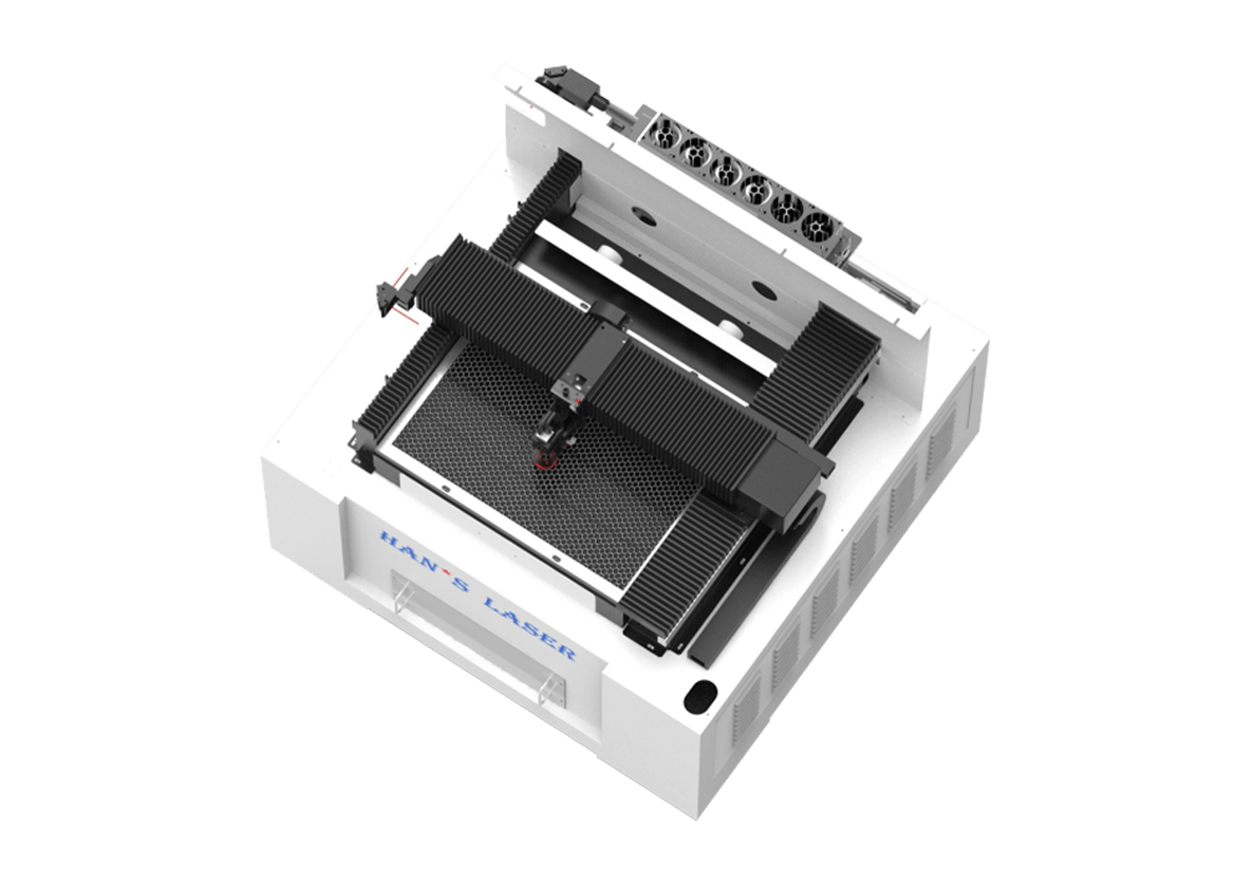

P5060-CO2-100 Laser Precision Cutting Machine

Full enclosed processing area.Our CO2 laser cutters are the perfect tools for engraving&cutting your favorite designs in acrylic, thin woods ,Silicone material,PCB,Plastic,rubber stamps,leather,glass and numerous more non-metal materials.

Under the CCD camera vision system,Precise positioning and precise cutting can be achieved.Onsite installation and training, and one year warranty

Contact us

Under the CCD camera vision system,Precise positioning and precise cutting can be achieved.Onsite installation and training, and one year warranty

Features

Application and Samples

Cutting for requirements with high precise consumer electronics industries,such as mobile shell,keypad sprue,touch screen,display conductive coating,display panel,and etc.

>PCB circuit board,PC panel,acrylic shell and rear-projection panel cutting.

>High precise electrical insulated soft board cutting.

>Curing some other materials which easy to generate smoke,such as button made frome resin material.

>Touch screen and cover FILM,wearable industry, and other non-metallic materials plane 2d precision cutting.

Technical Specs

| Laser Type | CO2 |

| Optional Laser Power | 100w |

| Work Piece Size Accuracy | 100w |

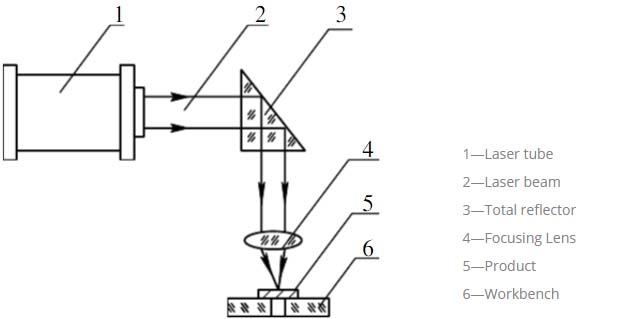

Laser cutting is the process of cutting material by means of electron discharge as the energy source.The following diagram describe the principle of Laser cutting Succinctly.P5060 Series Laser Cutter applications: wood, conductive film, paper, acrylic board and PET film.Laser cutting technology is an ideal solution for modern factories to improve cutting technology, and also an ideal way for family workshops to enter into modern processing industry.

Specification Sheet:

| Model | P5060-CO2-100 |

| Laser power | 100W CO2 |

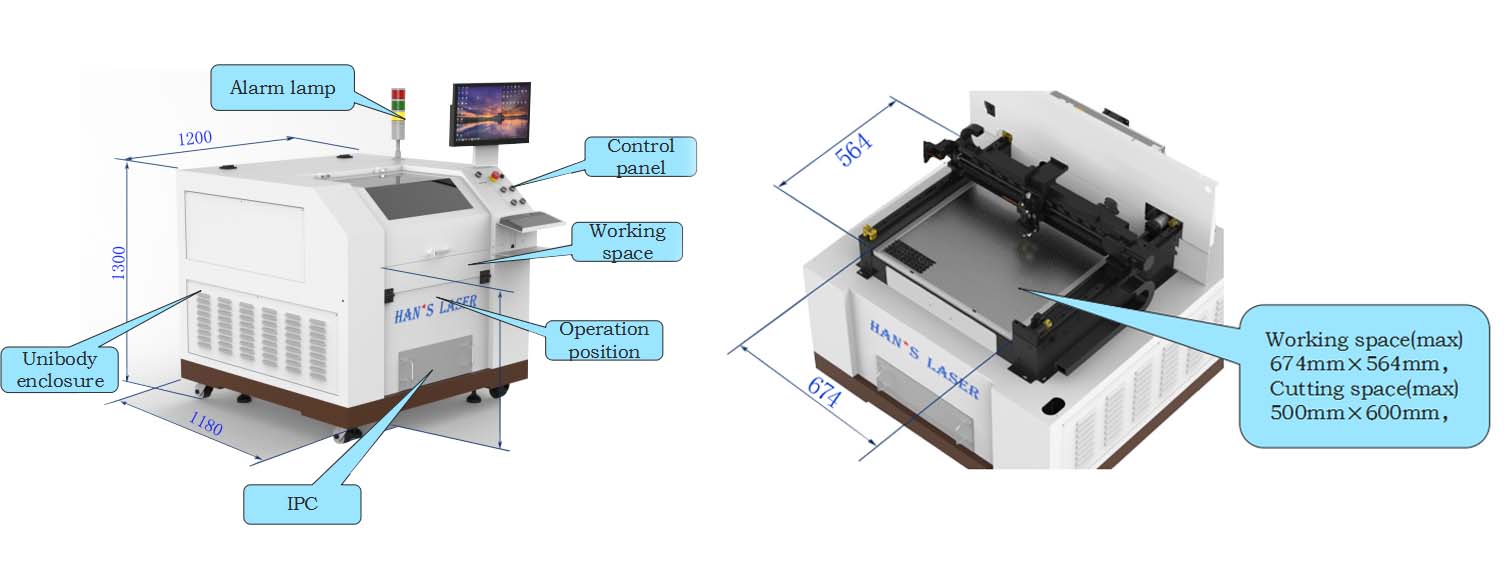

| X/Y axis travel | 23.62" x 19.68" (600 x 500mm) |

| Maximum placement of workpiece | 22.2" x 26.53" x 5.51" (564mm×674mmx140mm) |

| Processing effective area | 23.62" x 19.68" (600mm x 500mm) |

| Transmission structure | Servo motor,precision screw,Precision guide rail |

| Machine speed | 0~20 inch / sec (0~500mm/ sec) |

| Actual cutting speed (mm/ sec) | According to the material and laser. |

| Machine repeatability | ≤±0.01mm |

| Machine positioning accuracy | ≤±0.02 mm |

| Workpiece dimension accuracy | ≤±0.05mm (Related to the cutting material.) |

List of Machine Component

| Num | Project Name | Component Name | Quantity |

| 1 | Drive System | X axis lead screw | 1 |

| Y axis servo motor | 1 | ||

| X axis lead screw | 2 | ||

| Y axis servo motor | 1 | ||

| 2 | Optical System | Laser Tube | 1 |

| Optical Lens | 6 | ||

| Cutting Head | 1 | ||

| 3 | Mainbody of Machine | Steel Frame | 1 |

| 4 | Control System | Motion control board | 1 |

| Liquid Crystal Display | 1 | ||

| IPC | 1 | ||

| Special Cutting Software | 1 | ||

| 5 | Loactions system | CCD(optional) | 1 |

Options and Accessories

We have mature options and accessories to fit your specific application. A custom solution is always welcomed to consult.

ABOUT HAN'S LASER CORPORATION

Han's Laser Corporation is a wholly-owned subsidiary of Han's Laser Technology Group, a global industrial laser technology leader.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

CLIENTS