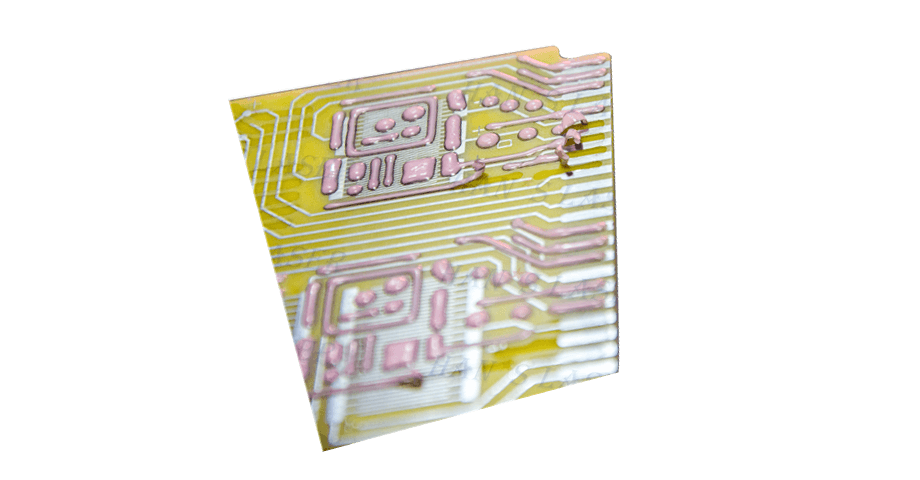

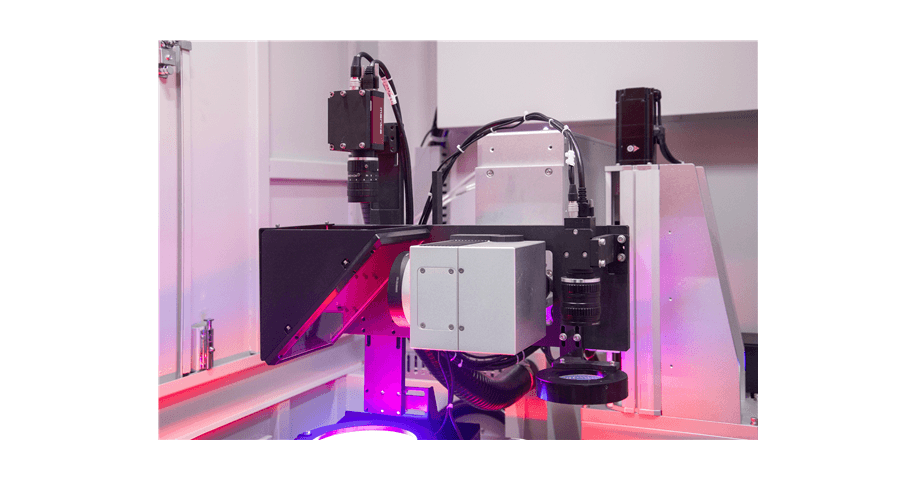

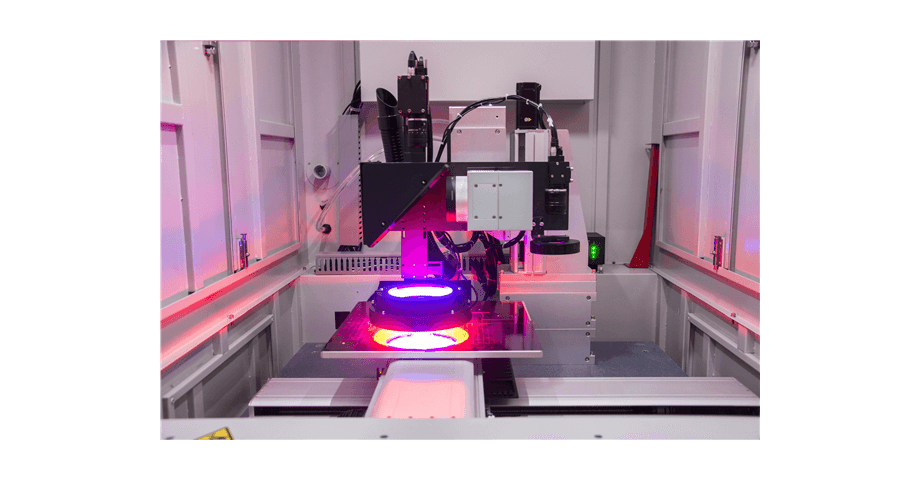

A process contour is generated by an intelligent CCD recognized system to make a quick de-coating without damaging the substrate surface.

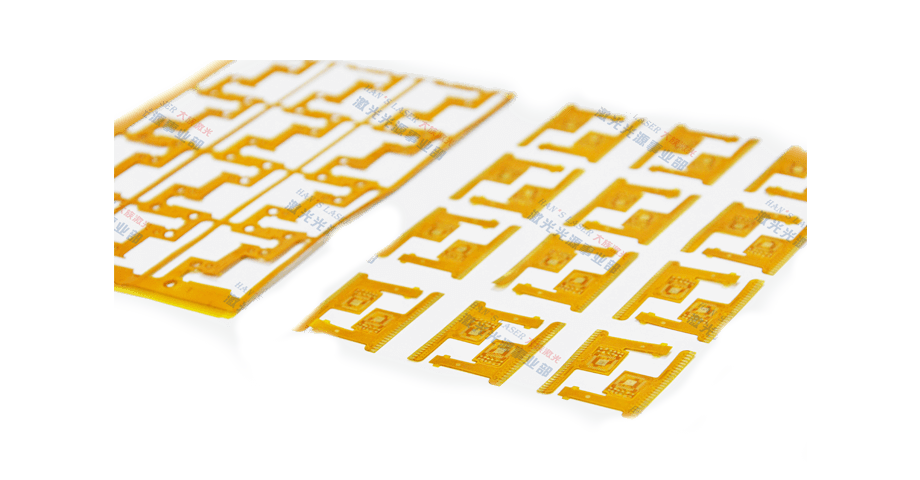

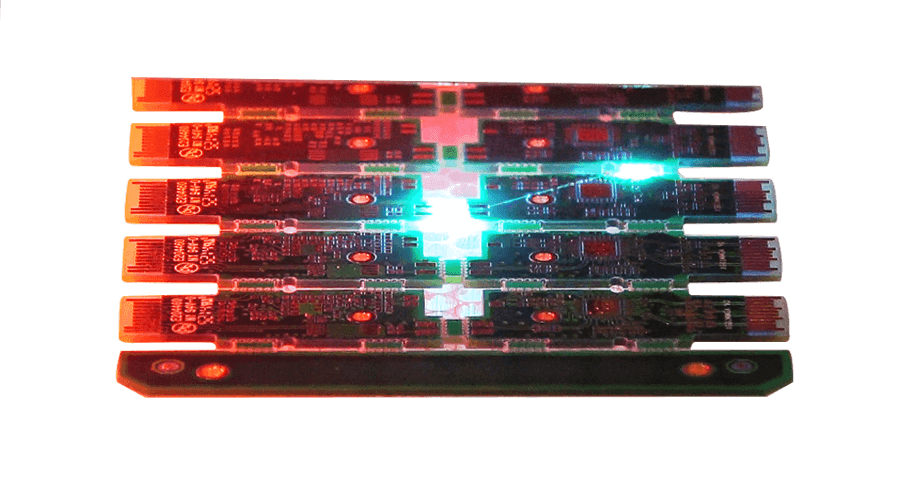

When the electronic components are inserted onto the PCB board identified as defective, they need to be removed and replaced with a functioning product. Before that, the glue stuck to the defective product needs to be removed. The traditional method of manual grinding or scraping is used, which is time-consuming, laborious, and the yield of PCB boards after this processing method is not high.

The laser glue removal method is environmentally friendly, has no chemical pollution, fast processing speed, and improved production efficiency.

- Dual intelligent vision CCD systems are used for the edge of the board and fiducial recognition

- The heat-affected zone and material deformation are small

- Assemble with X, Y, Z three-axis high accuracy working table

- Low running cost, an ideal alternative solution to replace hand removal

- The software supports Serial Port and TCP/IP communication with the client-server

| Laser Type | UV De-coating |

| Wavelength | 355 nm |

| Min Beam Diameter | < 10 µm |

| Beam Quality M2 | < 1.2 |

| Pulse Frequency | 10 - 200 kHz |

| Output Power | 4 Watts |

| Repetition Accuracy | ± 0.0001'' (0.003mm) |

| Cooling System | Water-cooled |

| Vision System | high-performance CCD camera |

| Operation System | WINDOWS 7 /10 |

| Laser Safety Level | Class I |

| Electrical Connection | 110 - 230 V (± 10%) 16 A,50/60 Hz |

| Power Consumed | 2 kW |

| Warranty Coverage | 1- year |

| Laser Safety Compliance | FDA(CDRH) |

| Running Temperature | 15℃-35℃ / 59°-95°F |

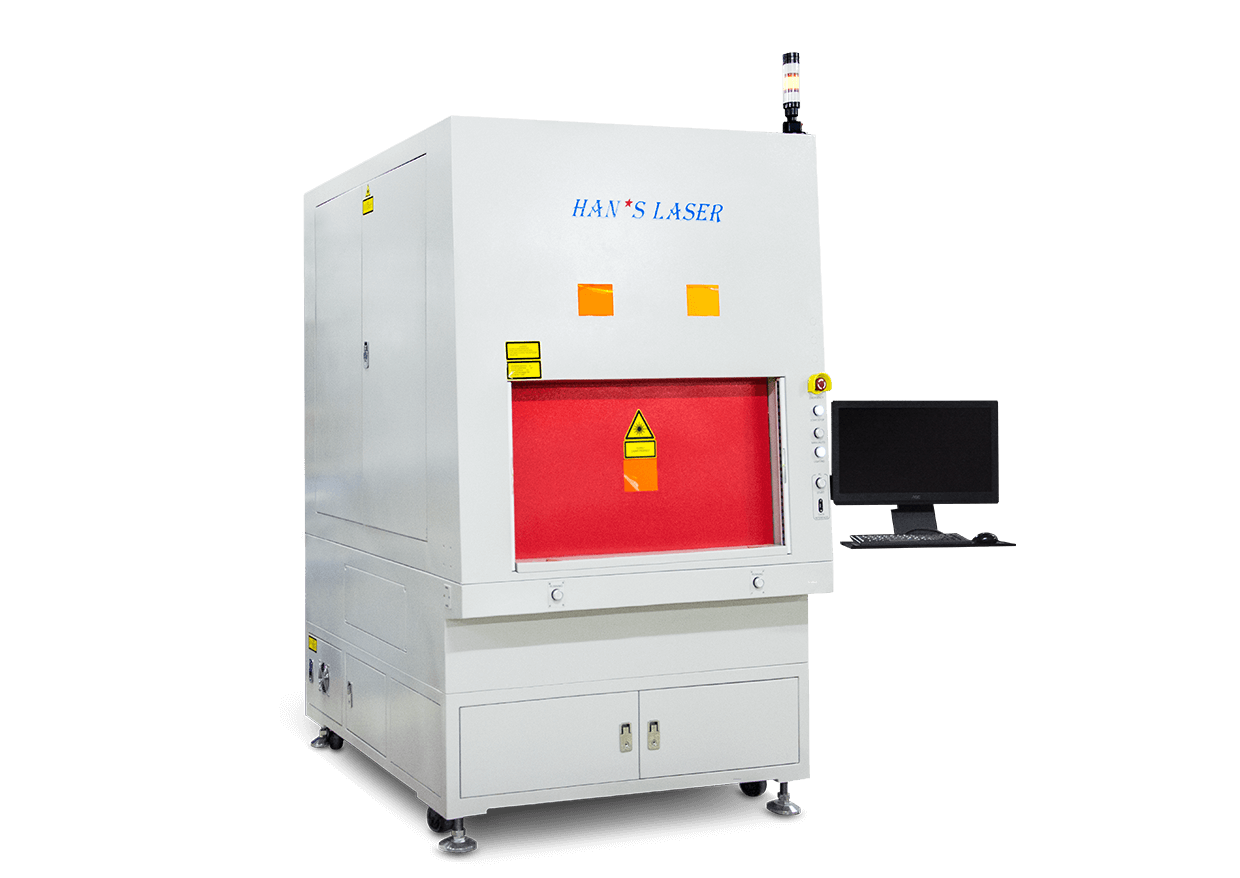

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.