3 W UV laser marking machine, 4 W, 7 W, 10 W, 15 W or specified laser power can be customized to meet the production requirement.

UV-3C-S is a standard single-station design. A turntable dual working station is an optional classic design.

Class 1 safety design is used to ensure the safety of the operator.

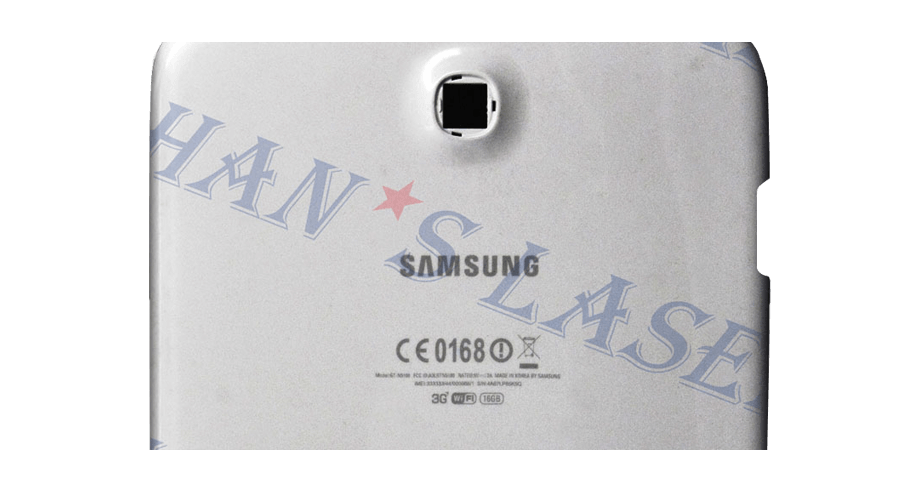

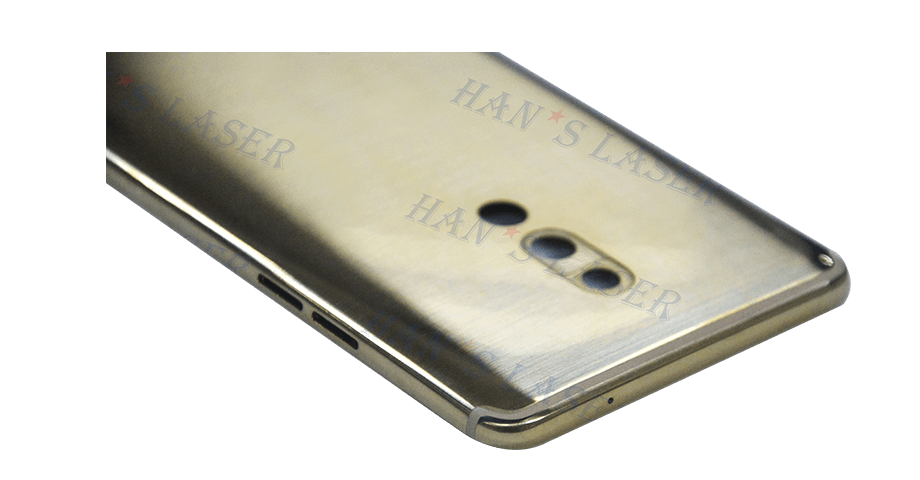

Han's Laser UV laser marker quality has been proven in the market for over ten years. More than 50,000+ Han's Laser UV laser marking machines work with contract manufacturers to help produce electronic parts, auto parts, IC chips, and other high value-added products.

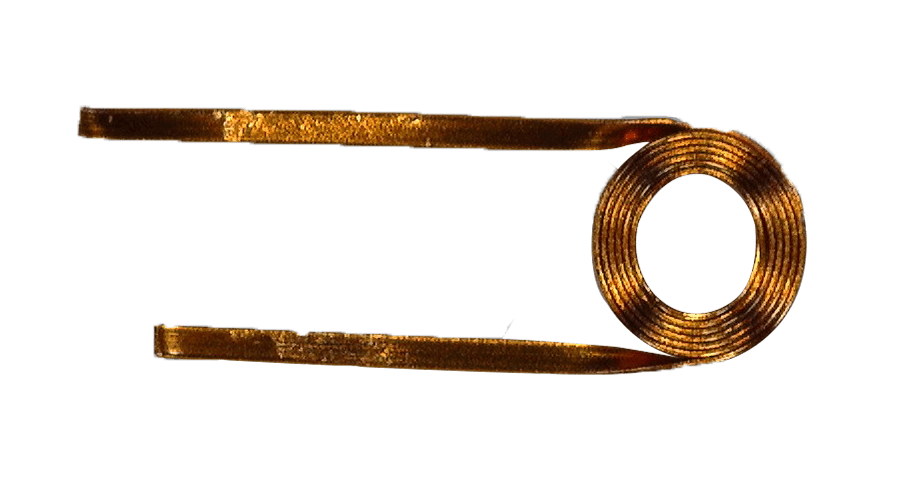

The UV laser marking machine uses a 355 nm wavelength UV laser with a "cold marking" method. The laser beam diameter is only 20 μm after focusing. The UV laser's pulse energy comes in contact with the material in the microsecond. There is no significant thermal influence next to the slit, so no heat damages the electronic component.

- With cold laser processing and a small heat-affected zone, it can achieve high-quality processing

- Wide applicable materials range can compensate for the shortage of infrared laser processing ability

- With good beam quality and a small focusing spot, it can achieve superfine marking

- High marking speed, high efficiency, and high precision

- No consumables, low cost and low maintenance fee

- The overall machine has stable performance, supporting the long-term operation

| Laser Type | UV Laser |

| Wavelength | 355nm |

| Min Beam Diameter | < 10 µm |

| Beam Quality M2 | < 1.2 |

| Pulse Frequency | 10 - 200 kHz |

| Output Power | 3 Watts |

| Repetition Accuracy | 3 μm |

| Cooling System | Water-cooled |

| Marking Field Size | 3.93" x 3.93 (100mm x 100mm) |

| Operation System | WINDOWS 10 |

| Laser Safety Level | Class I |

| Electrical Connection | 110 - 230 V (± 10%) 15 A, 50/60 Hz |

| Power Consumed | ≤1500W |

| Dimensions | 31.96" x 33.97" x 67.99" (812mm x 863mm x 1727mm) |

| Weight (unpacked) | 980 lbs (445kg) |

| Warranty Coverage | 1-year |

| Running Temperature | 15℃-35℃ / 59°-95°F |

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.