Contact us

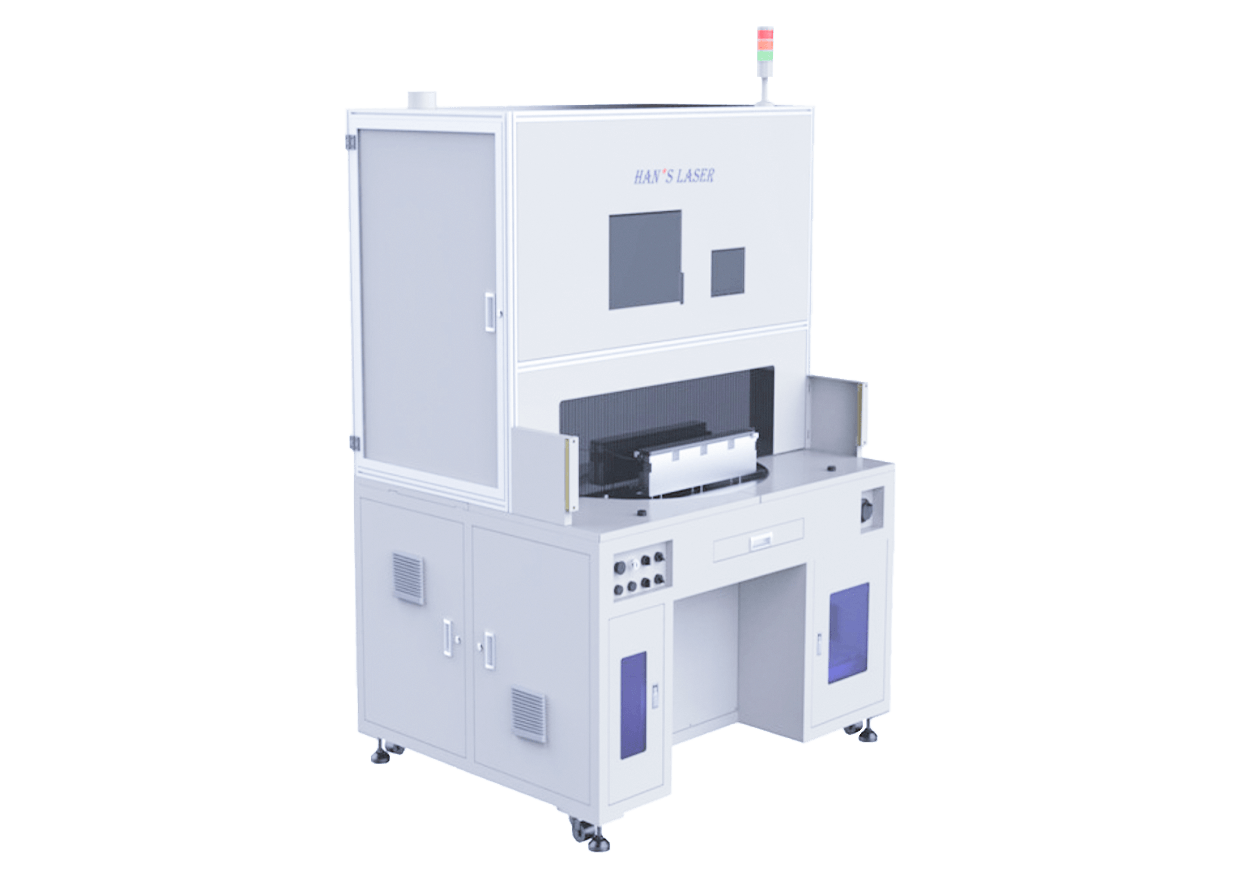

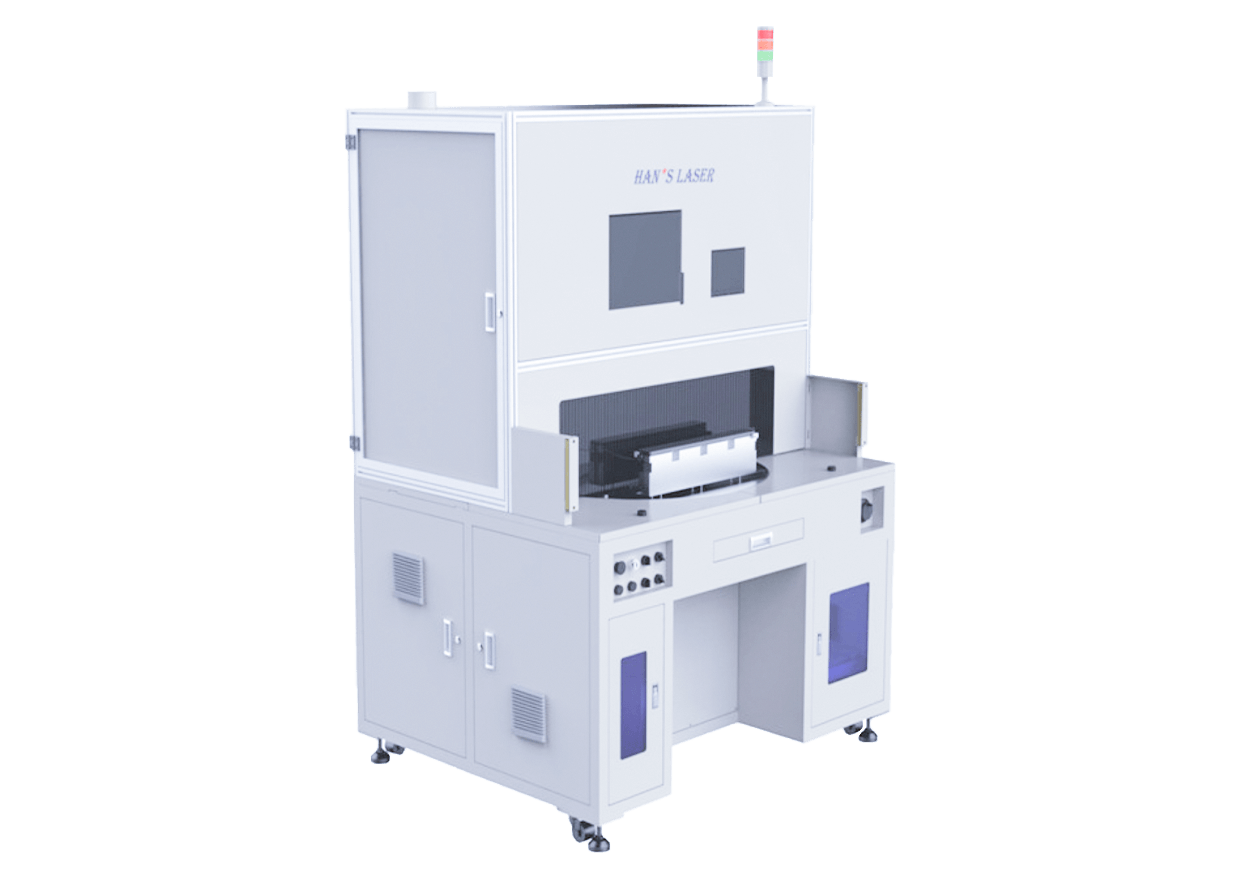

Laser Plastic Welding Machine- WFD Series

Laser welding machine for translucent, clear material.

The WFD series is a diode laser that uses diode materials to illuminate between energy bands. Two parallel mirror surfaces inside the diode are formed as a resonant cavity, which illuminates the light, and outputs laser of wavelength 915 nm.

With fiber transmission, a non-contact long-distance operation is convenient for integration with the automated production line. The laser has current feedback closed-loop control, real-time monitoring and adjustment of the output laser to ensure the stability; uniform beam energy distribution, large beam size.

For metal welding it is suitable for wide welding, the surface of the weld is smooth and clean. For welding plastic, with large beam size, the plastic at the joint is evenly melted, to create strong welding and perfect sealing.

Contact us

The WFD series is a diode laser that uses diode materials to illuminate between energy bands. Two parallel mirror surfaces inside the diode are formed as a resonant cavity, which illuminates the light, and outputs laser of wavelength 915 nm.

With fiber transmission, a non-contact long-distance operation is convenient for integration with the automated production line. The laser has current feedback closed-loop control, real-time monitoring and adjustment of the output laser to ensure the stability; uniform beam energy distribution, large beam size.

For metal welding it is suitable for wide welding, the surface of the weld is smooth and clean. For welding plastic, with large beam size, the plastic at the joint is evenly melted, to create strong welding and perfect sealing.

Features

- Low maintenance costs and low power demand, zero material consumption, lifetime maintenance-free,electro-optical conversion efficiency up to 47%

- Integrated design, easy to integrate into a machine

- Compact design

- Large beam size

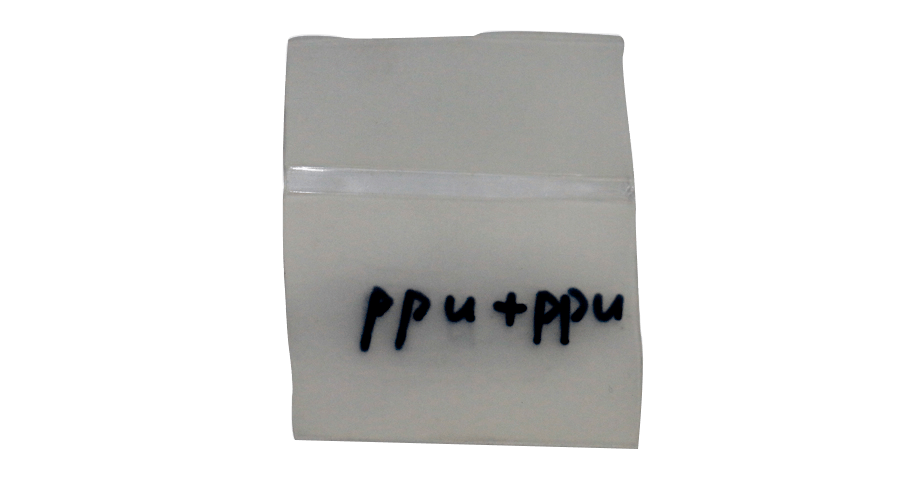

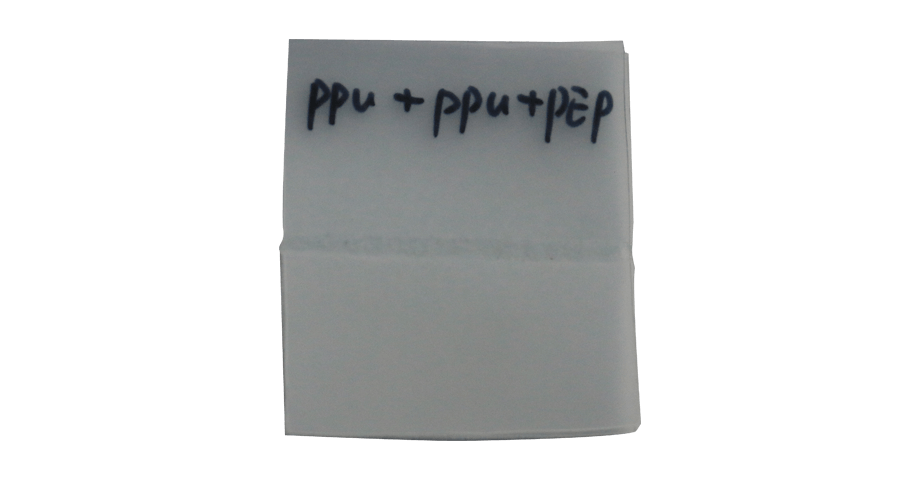

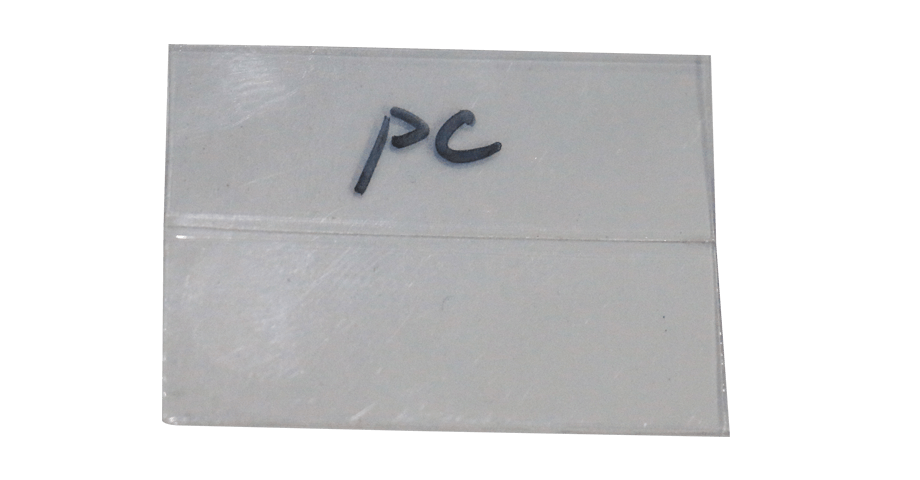

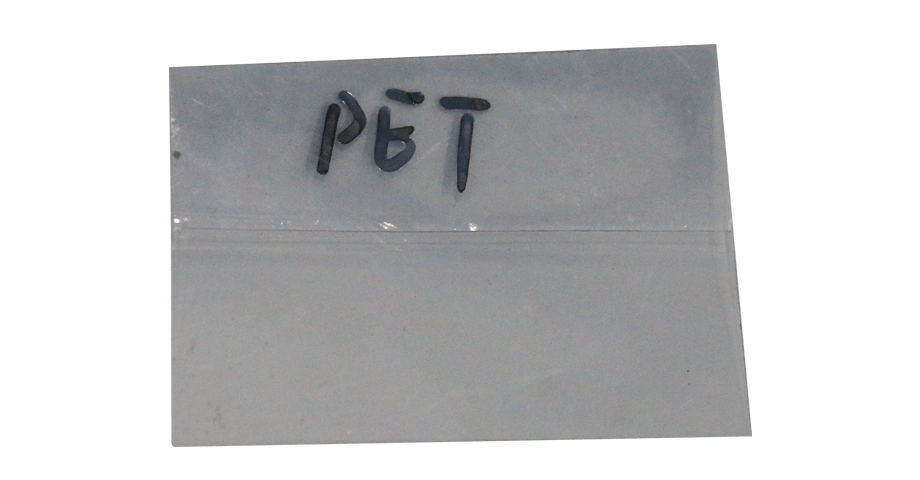

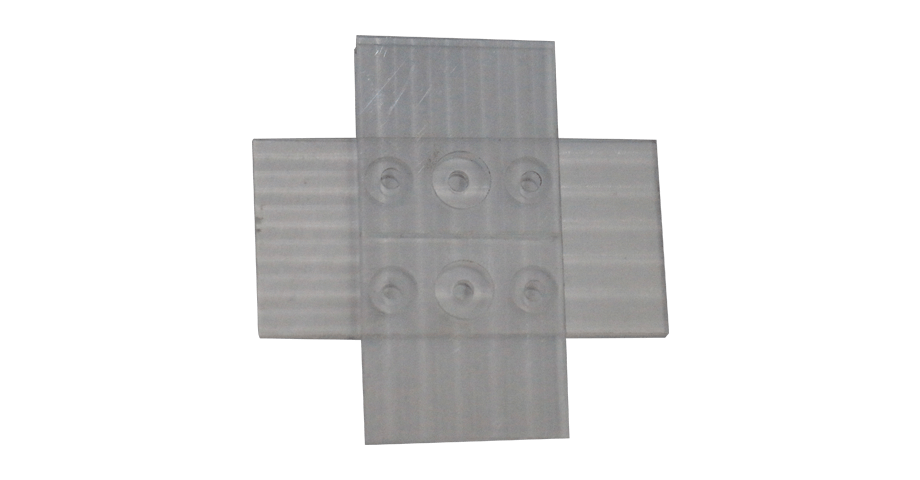

Application and Samples

As a kind of high molecular weight polymers material, plastic has been widely used in various industrial fields. Plastics are mainly composed of resin and can be divided into thermoplastic and thermosetting plastics according to the molding method.

Thermoplastics become soft after heating, solidify and shape after cooling, and the process is repeatable. Common materials include,

General plastics, such as polyethylene (PE), polyvinyl chloride (PVC), polypropylene (PP), polystyrene (PS), acrylonitrile-butadiene-styrene (ABS), polymethyl Methyl acrylate (PMMA);

Engineering plastics, such as nylon (Nylon), polycarbonate (PC), polyurethane (PU), polytetrafluoroethylene (Teflon, PTFE), polyethylene terephthalate (PET), etc.;

Special plastics, such as "artificial heart valves," "artificial joints," and "medical polymers."

The thermosetting plastic becomes soft after initial heating, and after reaching a specific temperature, it becomes solidified and formed with a chemical change. This process is irreversible and irreproducible. Common materials include phenolic resin (PF), epoxy resin (EP), amino resin, unsaturated polyester resin (UP) and so on.

After the plastic is molded, it will undergo secondary processing, and the most important thing is to connect the plastic according to various needs. Generally, plastic connection methods include glue bonding, ultrasonic welding, friction welding, thermal welding, and laser plastic welding. Among them, laser plastic welding has been used in more and more applications.

Most of the current laser plastic welding is for colored plastics, or it is necessary to add additives for auxiliary welding. These plastics are widely used in industries such as automotive electronics or mobile phones.

For some special fields, like biomedical fields and LED lightboxes, which require no additives applied. The common materials include polymethylmethacrylate (PMMA), polycarbonate ( PC), acrylonitrile-butadiene-styrene (ABS), cyclic olefin copolymer (COC) and others. These transparent plastics are difficult to use ordinary laser welding because of the low absorption rate for visible light or near-infrared light. Han's Laser has 2 microns wavelength laser plastic welding solution to accommodate this kind of demand.

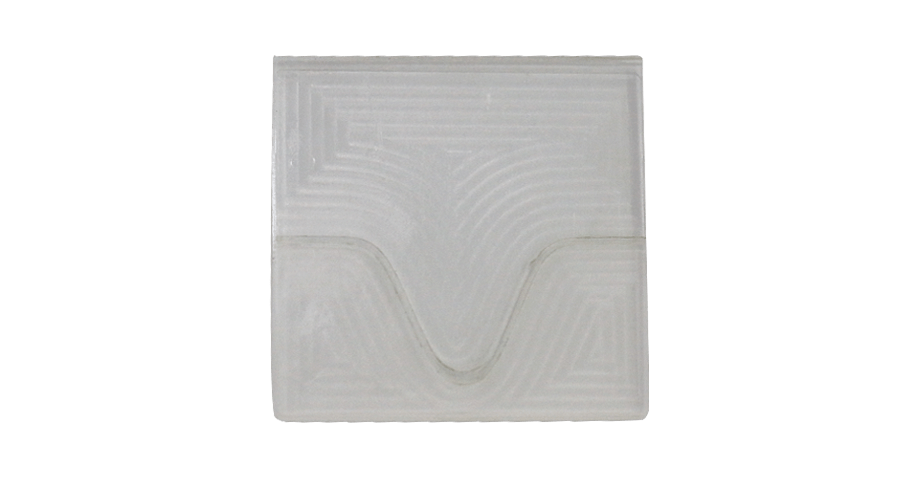

Laser welding plastic, the laser beam, after transmission through the upper-layer transparent material, will be absorbed by the lower layer. The laser energy, after being absorbed, will be transformed into heat. Since two layers of materials are forced together, the heat will be conducted to transparent layer from absorbing layer, which would make the two layers of materials melt and connected. At the same time, the internal pressure occurs because of the material’s thermal expansion. The total effort of the internal and external pressure can make sure two layers are firmly welded. For the product lower-layer material does not absorb laser, additive needs to be applied to the lower layer.

Almost all thermoplastics and thermoplastic elastomers can use laser welding technology. Commonly used welding materials are PP, PS, PC, ABS, polyamide, PMMA, POM, PET and PBT. However, some other engineering plastics, such as polyphenylene sulfide PPS and liquid crystal polymer, are not suitable for laser welding technology because of their low laser transmittance. Therefore, addictive is often added to the underlying material so that it can absorb enough energy to meet the requirements of laser transmission welding.

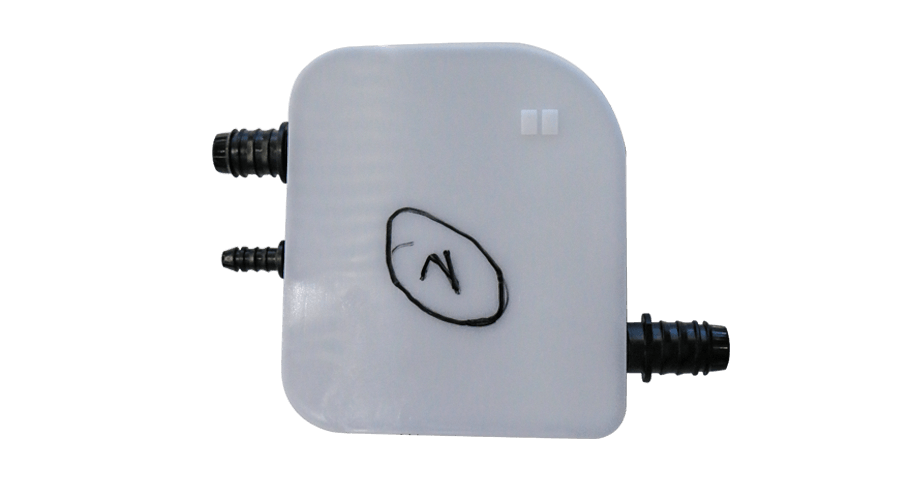

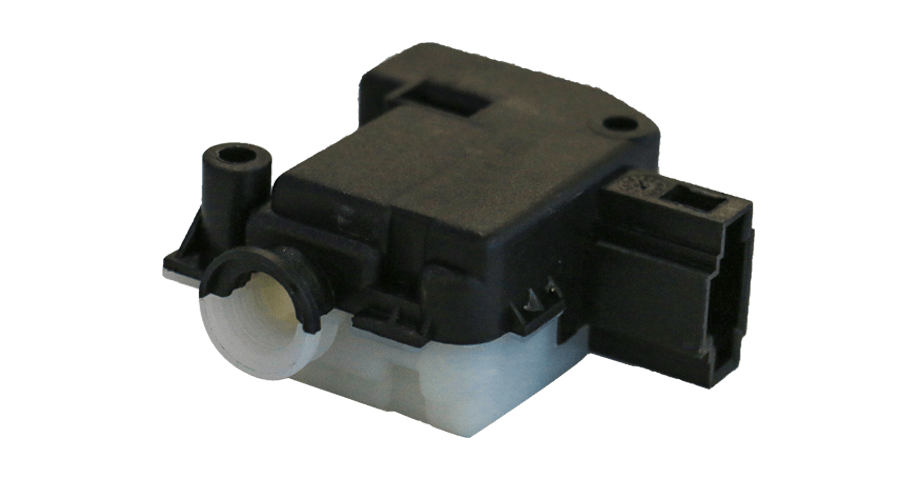

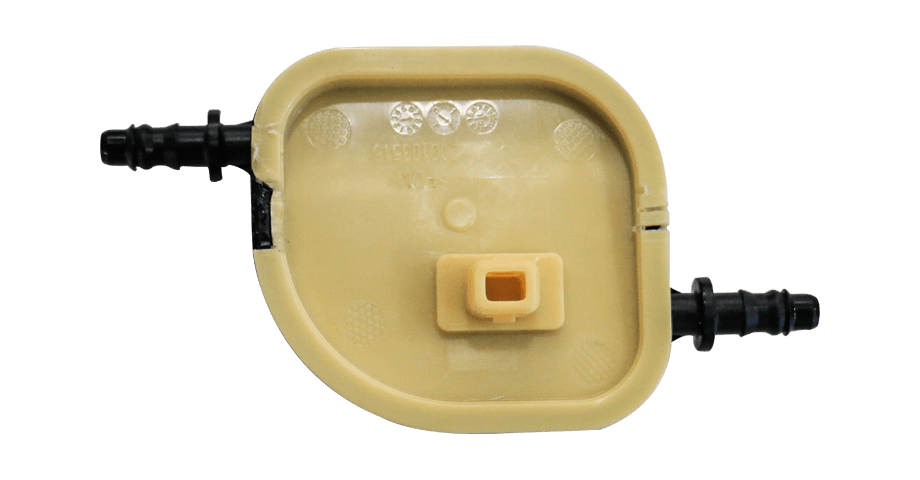

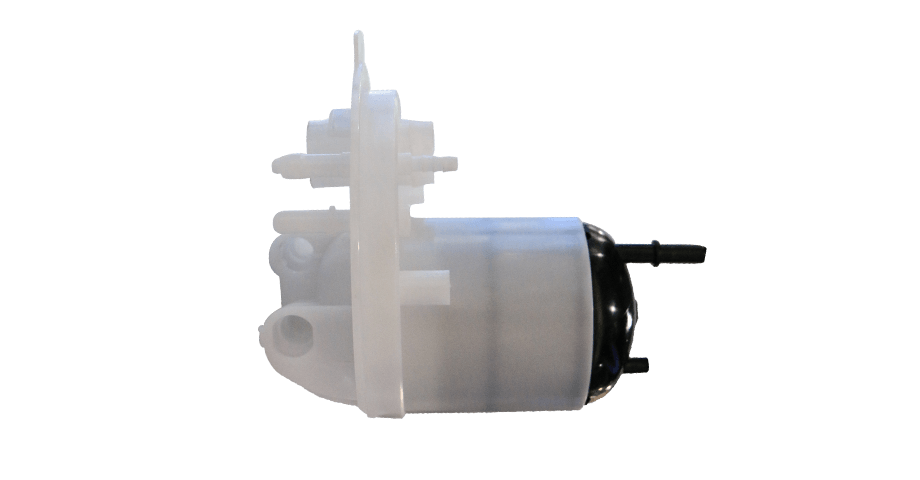

Widely applied to the reinforcement and sealing welding of plastics Medical plastic parts.

- Auto plastic parts

- Plastic bottle sealing welding

- Plastic pipe sealing welding

- Oxygen mask sealing welding

Application of laser plastic welding in the automotive industry

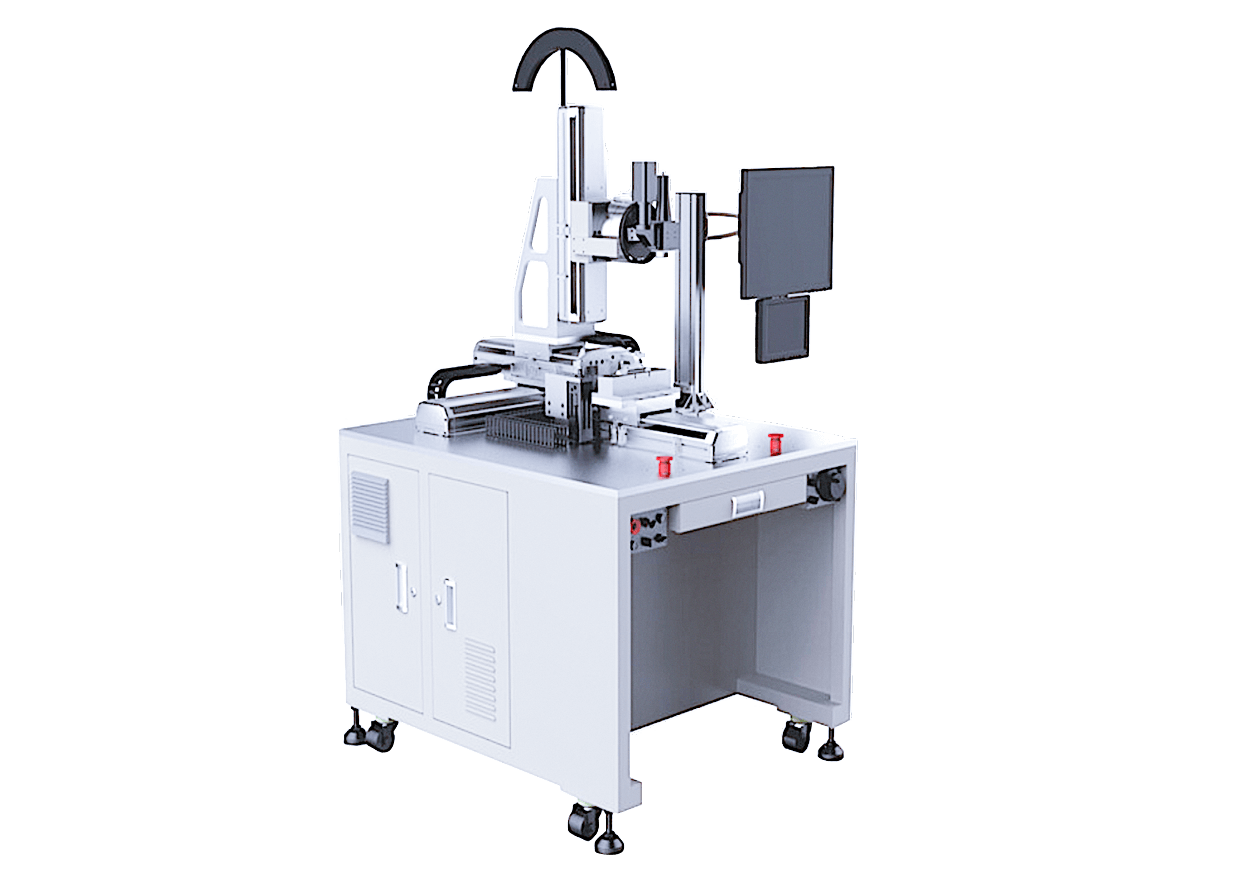

- Suitable for welding plastic bodies such as automobile taillights. The worktable adopts a three-axis method. The product is manually loaded on the fixture, and the Y-axis is fed to the welding position for rapid welding.

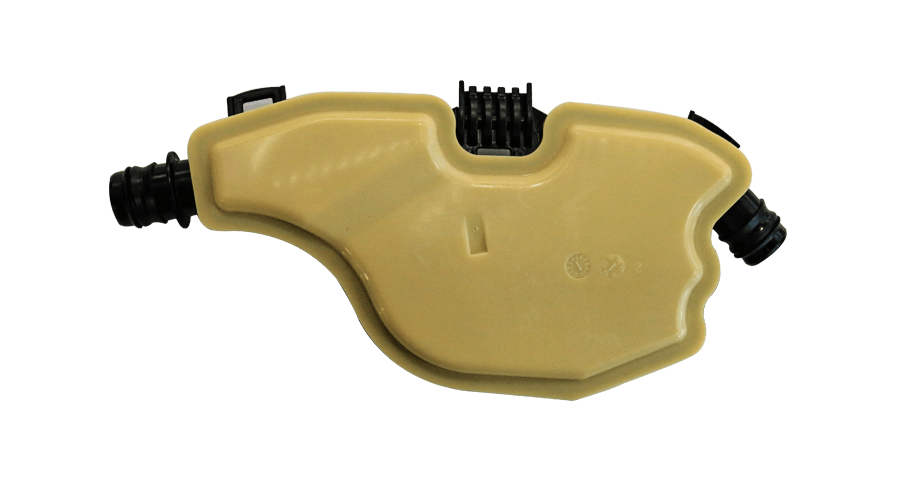

- Suitable for the welding of automobile automatic door locks and other similar products. The workbench adopts double Y-axis and dual station mode to realize the simultaneous loading and unloading and laser welding, which improves the laser's utilization rate.

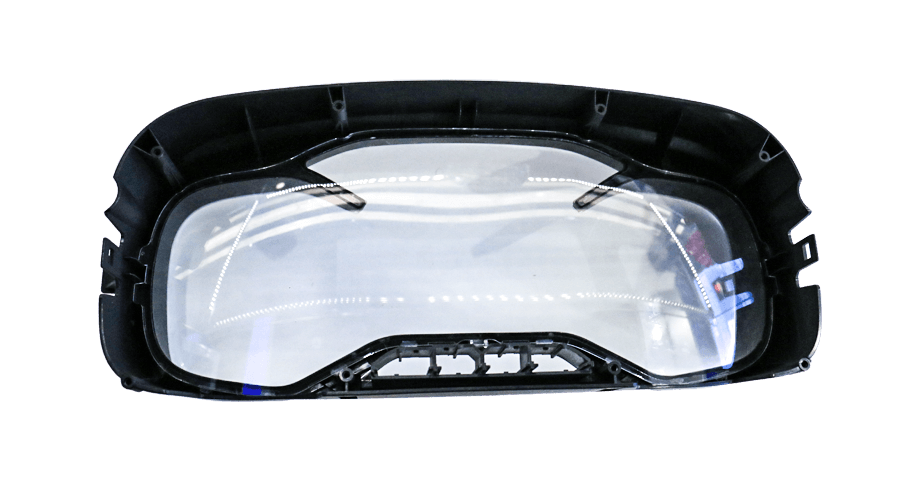

- Suitable for welding of automobile dashboards and other similar products. The worktable adopts manual loading and unloading and Y-axis feeding. Weld the product through the four-axis linkage welding head.

-

- Suitable for the welding of automobile automatic door locks and other similar products. The workbench adopts double Y-axis and dual station mode to realize the simultaneous loading and unloading and laser welding, which improves the laser's utilization rate.

- Suitable for welding of automobile dashboards and other similar products. The worktable adopts manual loading and unloading and Y-axis feeding. Weld the product through the four-axis linkage welding head.

-

Technical Specs

| Laser Model | WFD10 | WFD50 | WFD100 |

| Laser Type | Diode | Diode | Diode |

| Wavelength (nm) | 915 | 915 | 915 |

| Work Mode | CW | CW | CW |

| Maximum Average Power (W) | 10 | 50 | 100 |

| Pulse Width (ms) | 0.1~80000 | 0.1~80000 | 0.1~80000 |

| Wave Form | 16 x 16 sections | 16 x 16 sections | 16 x 16 sections |

| Fiber Output | 1 | 1 | 1 |

| Fiber Diameter (um) | 200 | 200 | 200 |

| Positioning Method | CCD Camera | CCD Camera | CCD Camera |

| Cooling System | Air-cooled | Air-cooled | Air-cooled |

| Power Input | 220V±10%,50/60 Hz | 220V±10%,50/60 Hz | 220V±10%,50/60 Hz |

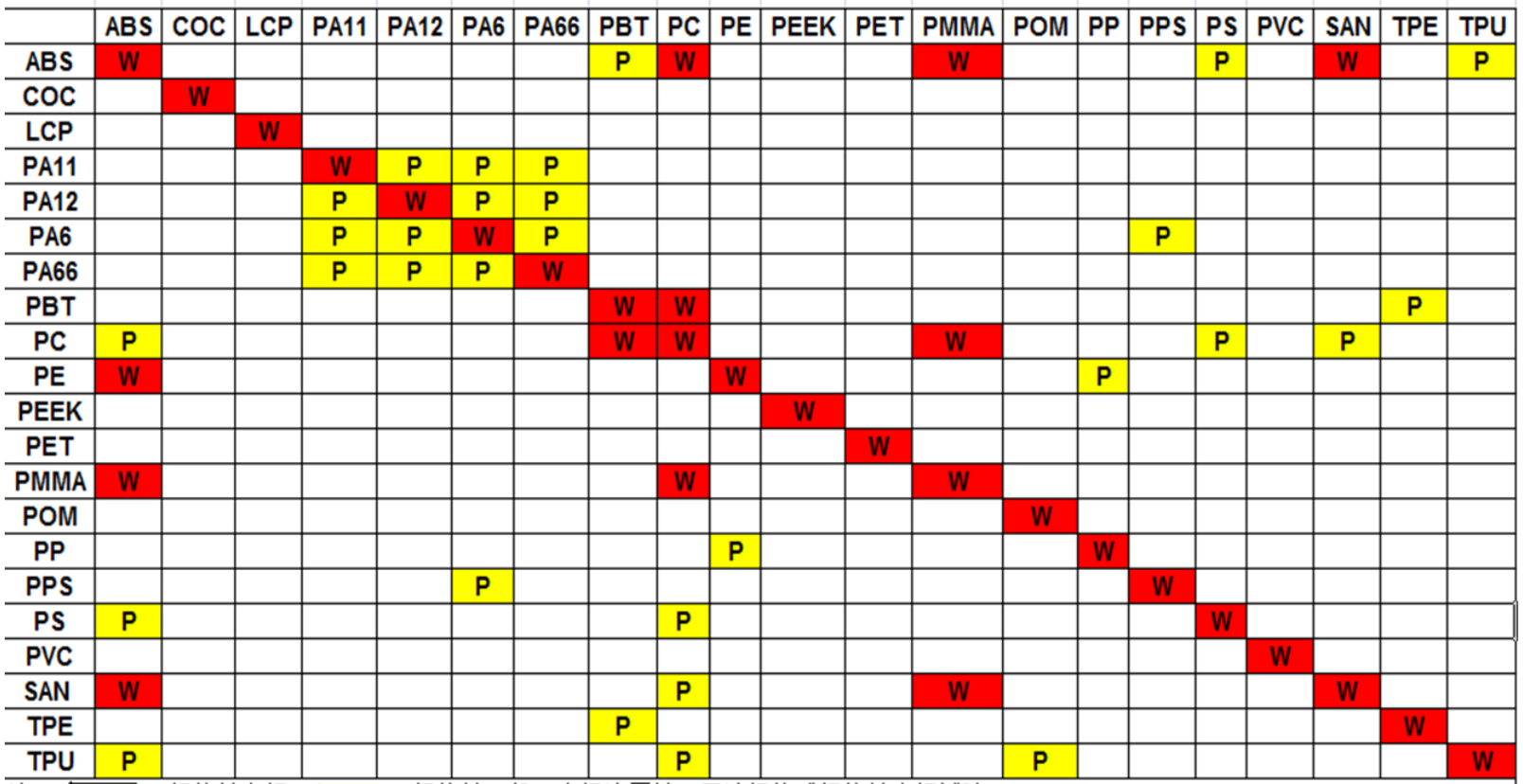

PLASTIC WELDING CHART

W - Perfect welding

P - Good welding

ABOUT HAN'S LASER CORPORATION

Han's Laser Corporation is a wholly-owned subsidiary of Han's Laser Technology Group, a global industrial laser technology leader.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

CLIENTS