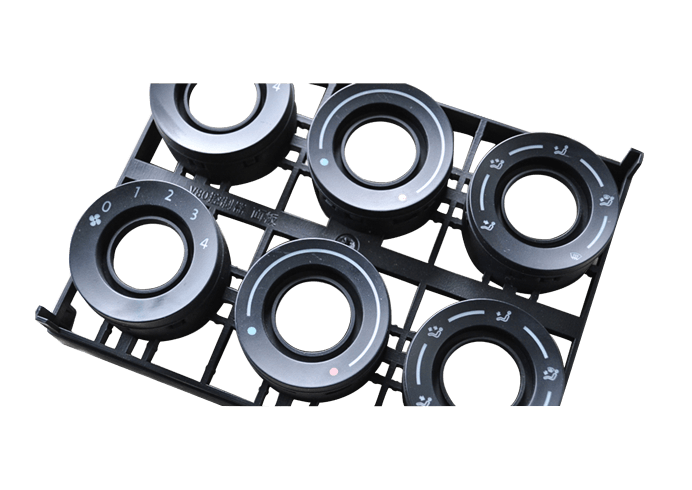

Laser Marking of Industrial Parts

Laser marking of industrial parts. Laser processing is non-contact, with no mechanical stress, suitable for processing requirements of high hardness (such as cemented carbide), high brittleness (such as a solar wafer), high melting point and precision products (such as precision bearings).

The laser processing energy density is very concentrated. The marking can be completed quickly, the heat affected area is small, the thermal deformation is minimal, and the processed product's electrical components are hardly damaged. The cold working of 532 nm, 355nm, and the 266nm laser is especially suitable for precision machining sensitive and critical materials.

Laser etching is a permanent mark, non-erasable, will not fail, will not deform and fall off, has anti-counterfeiting.

Able to mark 1D, 2D barcode, GS1 code, Series numbers, batch number, company information and logo.

Primarily used in integrated Circuit Chips, Computer Accessories, Industrial Machinery, Watches, Electronic and Communication products, Aerospace devices, Automotive parts, Home Appliances, Hardware Tools, Molds, Wire and Cable, Food packaging, Jewelry, Tobacco and Military industry design. Marking materials are respectively applied to Iron, Copper, Ceramic, Magnesium, Aluminum, Gold, Silver, Titanium, Platinum, Stainless Steel, Titanium Alloy, Aluminum Alloy, High Hardness Alloy, Oxide, Electroplating, coating, ABS, Epoxy Resin, Ink, Engineering, Plastic, etc.

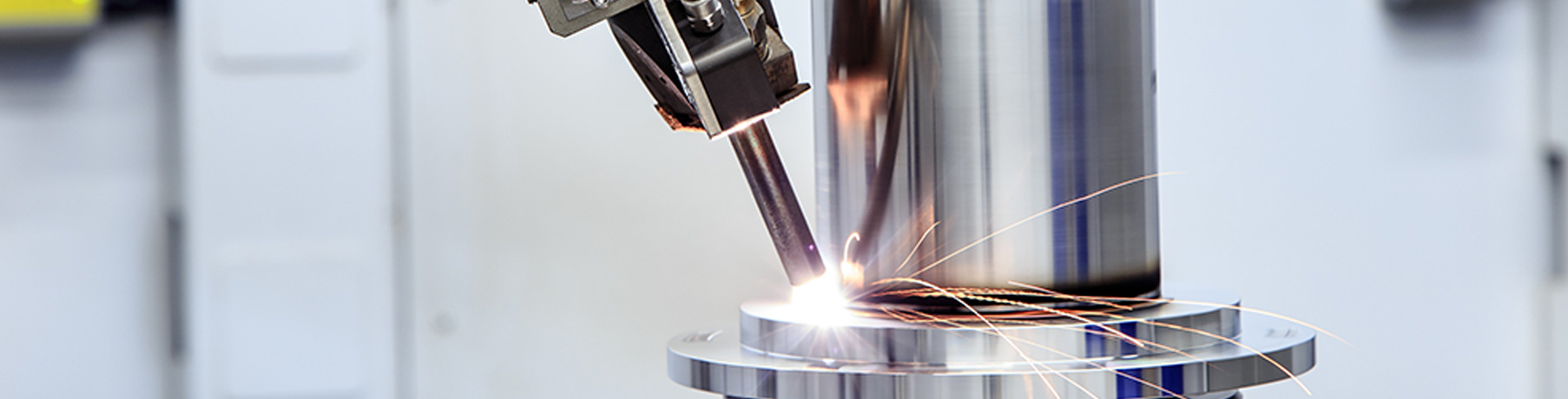

Laser Welding of Industrial Parts

Laser welding of industrial parts. Laser heating processes the surface of the product, and the surface heat diffuses into the interior through heat conduction. During the processing, the laser pulse width, energy, peak power, and repetition frequency are controlled to melt the workpiece to form a specific molten pool.

Laser welding includes continuous or pulses welding. The principle of laser welding can be divided into heat conduction welding and laser deep penetration welding. Power density less than 10~10 W/cm is heat conduction welding. The characteristics of heat conduction welding are shallow penetration and slow welding speed; when power density is greater than 10~10 W/cm, the metal's surface is heated into "cavities," forming deep penetration welding. This welding method is fast and has a significant depth to width ratio.

Laser welding technology is widely used in high-precision manufacturing fields such as automobiles, ships, airplanes, and high-speed railways.

Laser Cutting of Industrial Parts

Laser cutting of industrial parts. The laser can be focused into a tiny spot for micro and precision processing, such as micro slits and micro holes.

The laser can cut almost all materials, including two-dimensional cutting or three-dimensional cutting of metal plates. Laser processing does not require tools and is non-contact processing. Compared with mechanical processing, the deformation is minimal.

Compared with traditional processing methods, other advantages of laser cutting processing are also very prominent. The cutting quality is good, the cut width is narrow, the heat-affected zone is small, the cut is smooth, the cutting speed is fast, it can cut any shape flexibly, and it is widely used in different metal materials. Cutting. The high-precision servo motor with superior performance and the transmission guiding structure can ensure the machine's excellent motion accuracy at high speed.

High-speed laser cutting technology dramatically reduces the processing time and facilitates the processing at a low cost.

Laser Marking Machine Series

Laser Cutting Solution

Laser Cutting Machine Series

Laser Welding Solution

Laser Welding Machine Series

Laser Micromachining Solution

Micromachining Machine Series

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.