Contact us

MEDICAL DEVICE

All device identifiers (UDI) for medical devices, implants, tools, and instruments must be permanently, clearly and accurately marked. The laser-treated marking resists corrosion and undergoes a robust sterilization process, including centrifugation and autoclaving processes requiring high temperatures to obtain a sterile surface.

The fiber laser marking machine can mark UDI, manufacturer information, GS1 code, product name, and serial number, etc., which is undoubtedly the most suitable technology at present. Almost all medical products can be laser marked, including implants, surgical instruments and disposable products such as cannulas, catheters, and hoses. Markable materials include metal, stainless steel, ceramics, and plastics.

> READ MORE

INDUSTRIAL

Laser processing is non-contact, no mechanical stress, suitable for processing requirements of high hardness (such as cemented carbide), high brittleness (such as a solar wafer), high melting point and top precision products (such as precision bearings).

The laser processing energy density is very concentrated, the marking can be completed in a short time, the heat affected area is small, the thermal deformation is low, the thermal stress is small, and the electrical components inside the processed product is hardly damaged. The cold working of 532μm, 355μm, and the 266μm laser is especially suitable for precision machining of sensitive and critical materials.

> READ MORE

PCB

why Select Laser /

Laser depaneling is non-contact process technology, with no mechanical stress, no consumable worn blades.

The cutting pattern can be easily defined as user-friendly software. The vision system can recognize the accuracy marking position.

No realignment is required between the switch of different types of panels.

Low maintenance.

> READ MORE

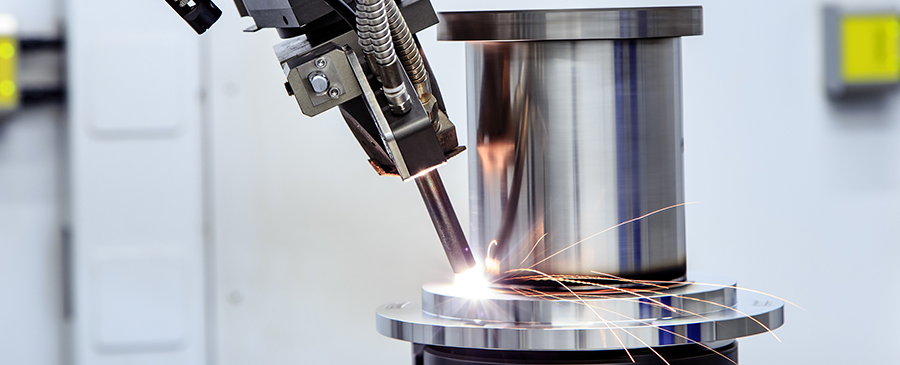

TOOLS&MOLD

The laser mold repairing machine is a welding technology that uses laser deposition welding to laser high heat energy and concentrates on fixed points, which can effectively handle all minor parts of welding and repair work. The above process is that the conventional argon gas welding and cold welding technology cannot be held exceptionally well in repairing the welding's fine surface.

The laser mold welding machine can weld all kinds of metal steel, such as 718, 2344, NAK80, 8407, P20, stainless steel, beryllium copper, aluminum alloy, titanium alloy, etc. There are no blisters, pores, collapse and deformation after welding. The bonding strength is high, the welding is firm, and it is not easy to fall off.

> READ MORE

JEWELRY

The laser engraving machine is ideal for permanent wear-resistant markings on precious and delicate jewelry surfaces such as rings and necklaces with a personalized message, greetings, and personalized patterns. Besides, the laser can engrave a variety of materials such as copper, stainless steel, silver, gold, gold, platinum, platinum and titanium.

> READ MORE

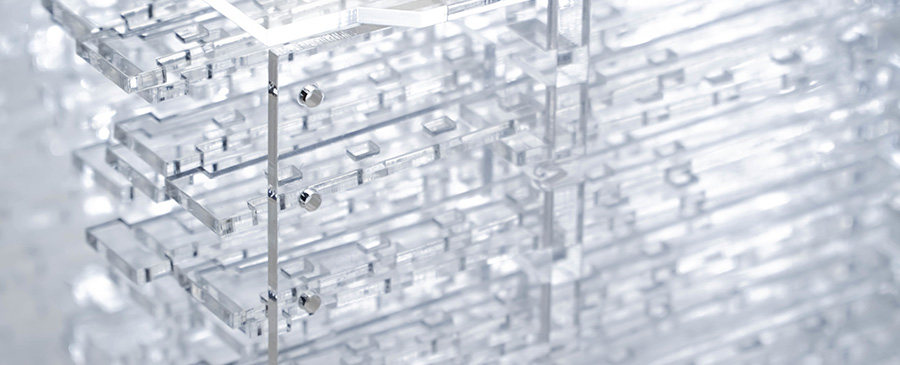

PLASTIC WELDING

The commonly used laser welding progress is called laser transmission welding. After transmission through the upper-layer transparent material, the laser beam will be absorbed by the lower layer. The laser energy, after being absorbed, will be transformed into heat. Since two layers of materials are forced together, the heat will be conducted to a transparent layer from the absorbing layer, making the two layers of materials melt and connected. At the same time, the internal pressure occurs because of the material’s thermal expansion. The total effort of the internal and external pressure can make sure two layers are firmly welded. For the product, the lower-layer material does not absorb laser. An additive needs to be applied to the lower layer.

> READ MORE

AUTO PARTS

Laser marking on car labels and nameplates.

Laser marking on automotive glass.

Laser marking on the wheel of a car.

Laser marking on automotive parts.

Including 2D code and other marks; logo, pattern, warning signs, etc.; label nameplate marking; automotive glass 3C certification and other markings; production date, serial number, batch number, etc.;

Laser welding of automotive transmission gears and planet carriers

Flywheel assembly, ring gear, and drive plate laser welding

Automobile shock absorber welding

Automotive sunroof welding.

Filter laser welding

Others

> READ MORE

SHEET METAL

Laser cutting is a sheet metal processing that laser beam radars on the processing material. Laser cutting works by directing the output of a high-power laser, most commonly through optics. The laser beam can be divided into a solid-state and un-solid state versus fiber laser and Co2 Laser. Fiber Laser’s wavelength is 1.06μm, 1/10 compare with CO2 Laser, easier to be absorbed by metal materials, higher cutting speed for cutting MS、SUS and SUS

> READ MORE

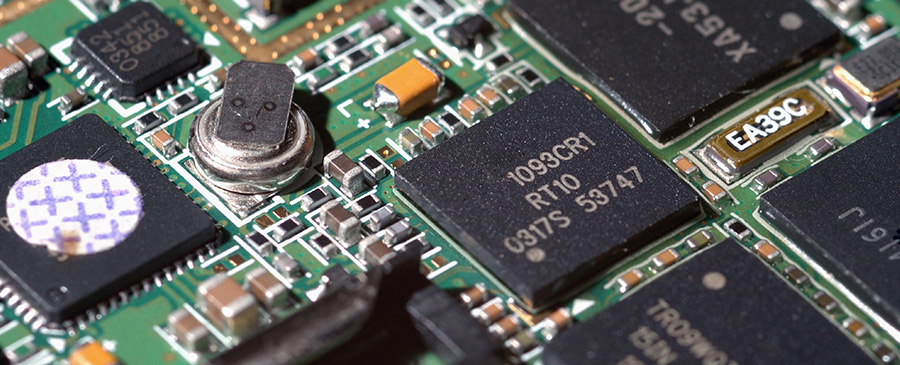

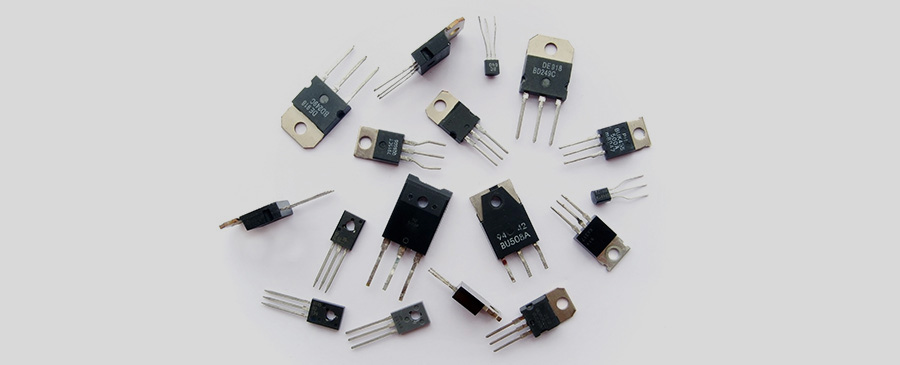

ELECTRONIC AND SEMI-CONDUCTOR

IC, Capacitor, Resistor, Wafter, and other electronic parts laser marking.

> READ MORE

GIFT AND SOUVENIR

What laser can do is more than your imagination!

Personalized wedding gift, Housewarming gift, Anniversary gift, Birthday or any special occasion.

The laser makes the one owned by you!

CO2 Laser Cutter, Mopa Fiber Laser Marker, UV Laser Marker, Green Laser Sub-surface Engraver, among of there, there will be one that you are looking for.

> READ MORE

ID / TAGS / SECURITY SEALS

Han's Laser offers you a complete laser marking solution for different kinds of animal tags, including cattle ear tags, sheep mini ear tags, visual ear tags, and cow ear tags.

Permanent Laser marking of logo and sequential number on the body of seals for enhanced security. No additive is required for application.

Good marking quality on industrial nameplates, labels and tags, which are made of metals and plastics.

> READ MORE

MECHANICAL HARDWARE

Han's Laser's range of laser cutting, welding, marking, drilling, and cleaning machines has made it possible to create complex, high-performance components that are essential for a wide range of industries, from automotive to aerospace to construction.

What laser can do is more than your imagination!

> READ MORE

ABOUT HAN'S LASER CORPORATION

Han's Laser Corporation is a wholly-owned subsidiary of Han's Laser Technology Group, a global industrial laser technology leader.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

CLIENTS