Contact us

Pico-second Laser Marking & Engraving Machine

The picosecond laser can mark rainbow color on stainless steel, titanium and black marking on anodized aluminum and stainless steel.

All device identifiers (UDI) for medical devices, implants, tools, and instruments must be permanently, clearly and accurately marked. Picosecond laser black marking is widely used in these fields.

The laser-treated marking resists corrosion and undergoes a robust sterilization process, including centrifugation and autoclaving processes requiring high temperatures to obtain a sterile surface.

The infrared picosecond laser is a no-contact, narrow pulse width ultra-fast process technique. It is a turnkey marking and cutting system. Nearly accommodate almost all types of medical products can be laser marked, including implants, surgical instruments and disposable products such as cannulas, catheters, and hoses.

Contact us

All device identifiers (UDI) for medical devices, implants, tools, and instruments must be permanently, clearly and accurately marked. Picosecond laser black marking is widely used in these fields.

The laser-treated marking resists corrosion and undergoes a robust sterilization process, including centrifugation and autoclaving processes requiring high temperatures to obtain a sterile surface.

The infrared picosecond laser is a no-contact, narrow pulse width ultra-fast process technique. It is a turnkey marking and cutting system. Nearly accommodate almost all types of medical products can be laser marked, including implants, surgical instruments and disposable products such as cannulas, catheters, and hoses.

Features

Compared with the traditional nanosecond laser (10^-9s), the picosecond laser has high processing accuracy, minimal thermal effect, and no burrs on the processing edge.

Picosecond lasers have been widely used in fine micromachining fields with the advantage of high peak power and narrow pulse width (10^-12s). Such as LED chip dicing, solar photovoltaics, rainbow color on stainless steel, titanium, and anodized aluminum black marking.

- Support CAD file format(DXF)/ PLT/BMP/JPG/AI

- Able to mark 1D, 2D bar code, GS1 code, Series numbers, Batch number, Logo, Company information

- Laser marking software could be customized to meet the customer's unique demand

- The software supports Serial Port and TCP/IP communication with the client-server

Application and Samples

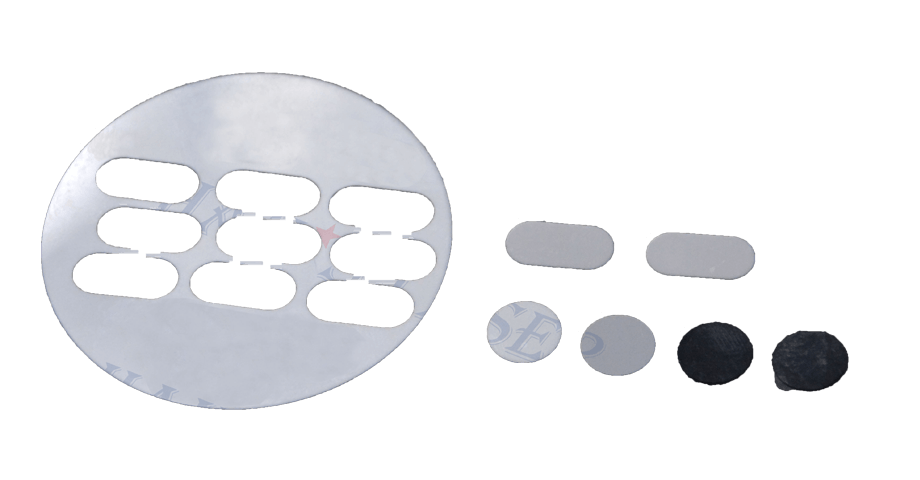

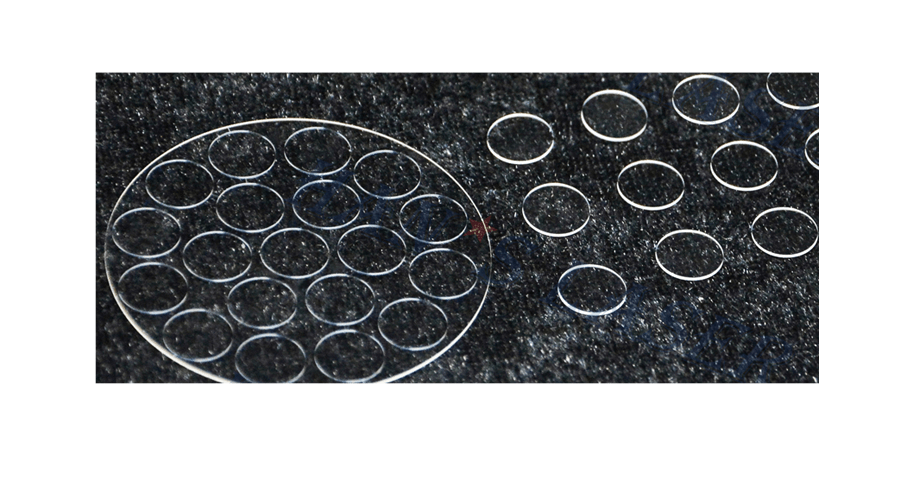

- LED chip dicing

- Solar

- Rainbow color on stainless steel

- Anodized aluminum black effect laser marking

- UDI marking of medical device

- UDI marking of medical device

Technical Specs

| Laser Type | Picosecond Laser |

| Wavelength | 1064 nm (nominal) |

| Min Beam Diameter | < 10 µm |

| Beam Quality M2 | < 1.2 |

| Pulse Frequency | 10 - 1000 kHz |

| Output Power | 30 Watts |

| Repetition Accuracy | ± 0.0001'' (0.003mm) |

| Cooling System | Fully Water Cooled |

| Marking Field Size | 3.93" x 3.93" (100mm x 100mm) |

| Operation System | WINDOWS 10 |

| Laser Safety Level | Class I |

| Electrical Connection | 110 - 230 V (± 10%) 16 A, 50/60 Hz |

| Power Consumed | 2KW |

| Dimensions | 32”L x 1117”W x 68”H (812mm x 863mm x1727mm) |

| Weight (Unpacked) | 980 lbs (445kg) |

| Warranty Coverage | 1-year |

| Laser Safety Compliance | FDA(CDRH) |

| Running Temperature | 15℃-35℃ / 59°-95°F |

Options and Accessories

3 Axis XYZ worktable, Rotary attachment, Jewelry magic grip, Rubber roller, F-Theta focal lens.

ABOUT HAN'S LASER CORPORATION

Han's Laser Corporation is a wholly-owned subsidiary of Han's Laser Technology Group, a global industrial laser technology leader.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

CLIENTS