Contact us

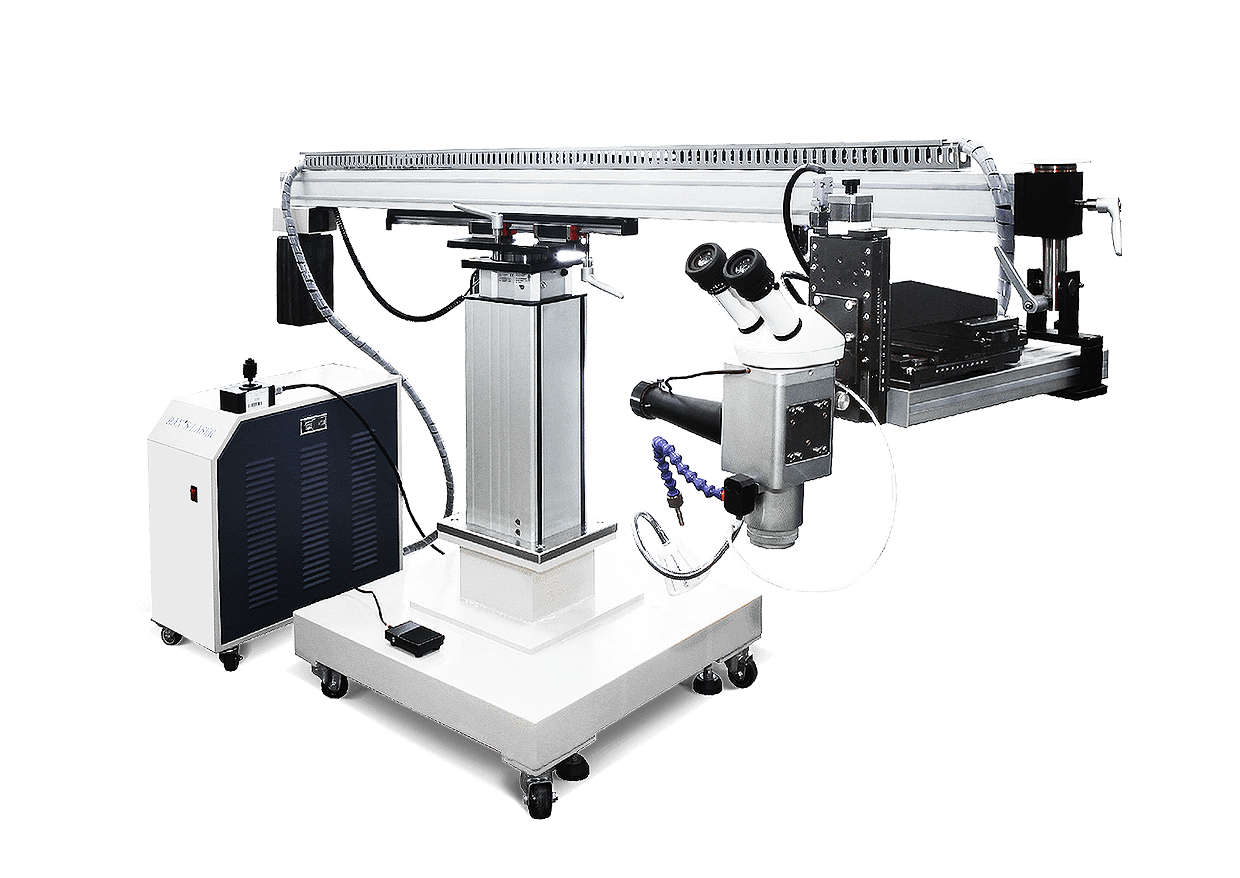

Laser Mold Repair Welding Machine Mold 301/302

This is an optical fiber transmission pulse laser machine. The optical fiber transmission welding machine greatly enhances the adaptive flexibility of laser welding.

The laser head is far away from the welding machine due to the laser's transmission through the optical fiber, and the laser transmission is flexible. Therefore the laser can process products that are challenging for other tools.

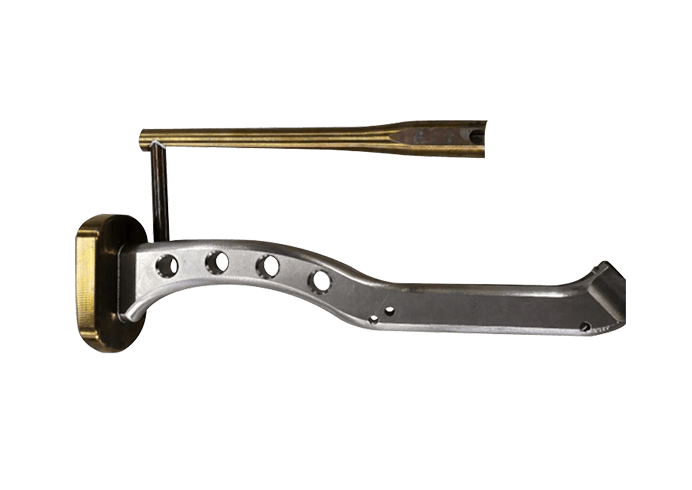

Equipped with a 3d motion NC worktable based on industrial rocker control, it can walk out of any irregular curve track, suitable for mold and product repairs. The table can also be equipped with a rotating table controlled by an industrial rocker to make a circular motion.

Contact us

The laser head is far away from the welding machine due to the laser's transmission through the optical fiber, and the laser transmission is flexible. Therefore the laser can process products that are challenging for other tools.

Equipped with a 3d motion NC worktable based on industrial rocker control, it can walk out of any irregular curve track, suitable for mold and product repairs. The table can also be equipped with a rotating table controlled by an industrial rocker to make a circular motion.

Features

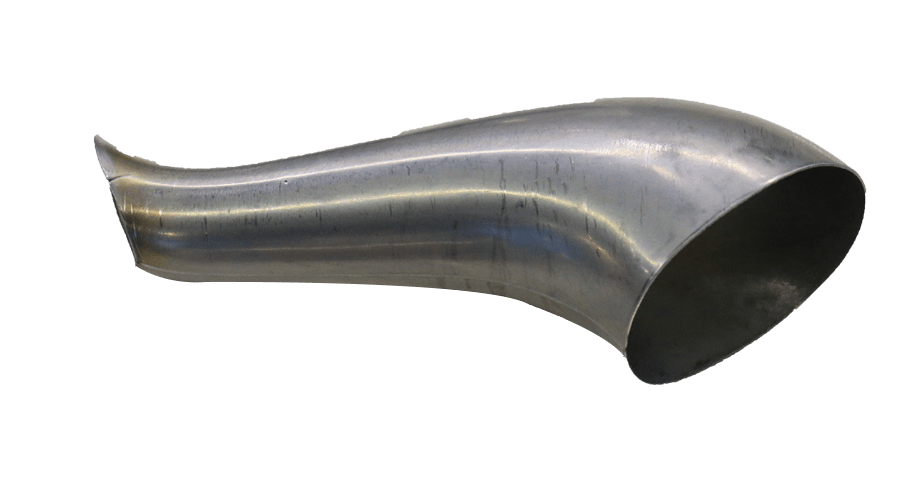

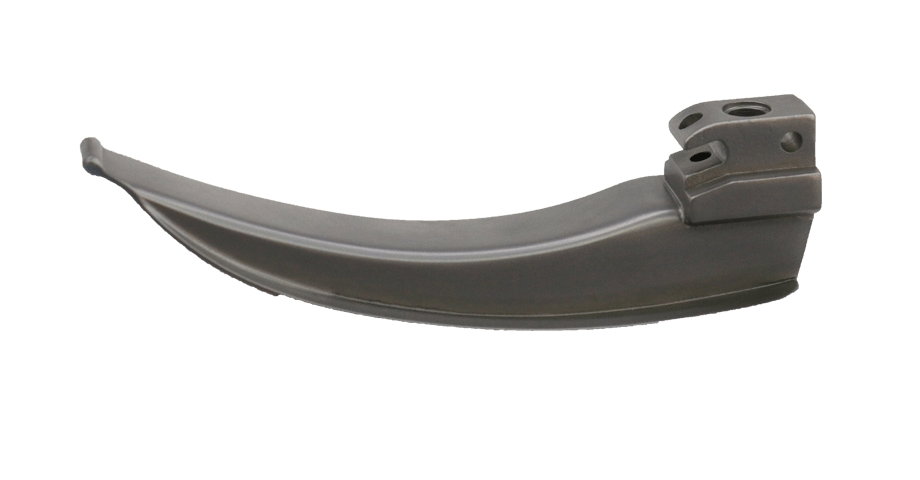

The laser mold repair welding machine can quickly and accurately repair the pores, slag holes, and shrinkage holes formed during the casting process.

Suitable materials for laser repair include ductile iron, gray iron, stainless steel, etc.

- Small thermal deformation and heat-affected zone (suitable for processing high melting point, high hardness, unique materials)

- Partial heat treatment can be performed on ordinary parts, parts with complex shapes or small. It can also be performed in a vacuum environment

- No preheat treatment is required, and the workpiece will not be annealed after welding

- No deformation of sags, no pores and trachoma

- It can be used to repair cracks, chippings, edges and corners, sand holes and mold wear after use

- The same hardness can be achieved after repairing with the same material as the base material

- The toughness of the cold die and the cutting edge of the tool can also be welded, eliminating the cumbersome preheating and heat preservation processes of ordinary argon welding

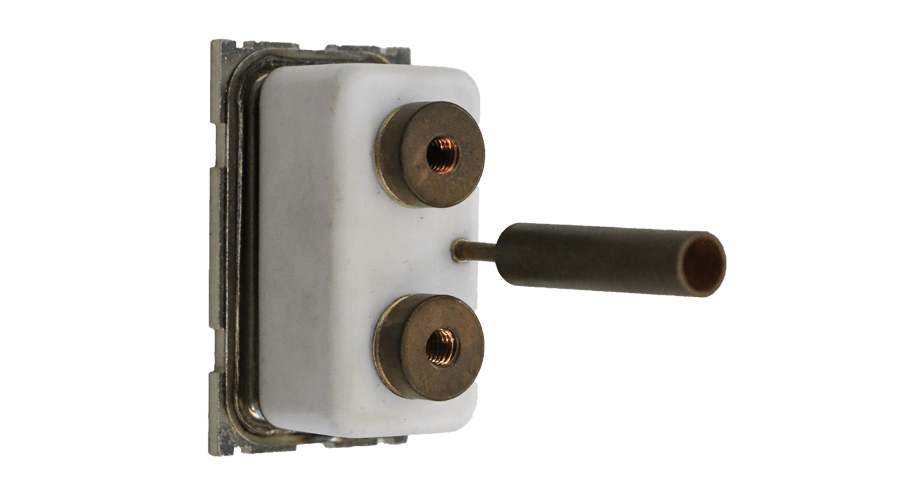

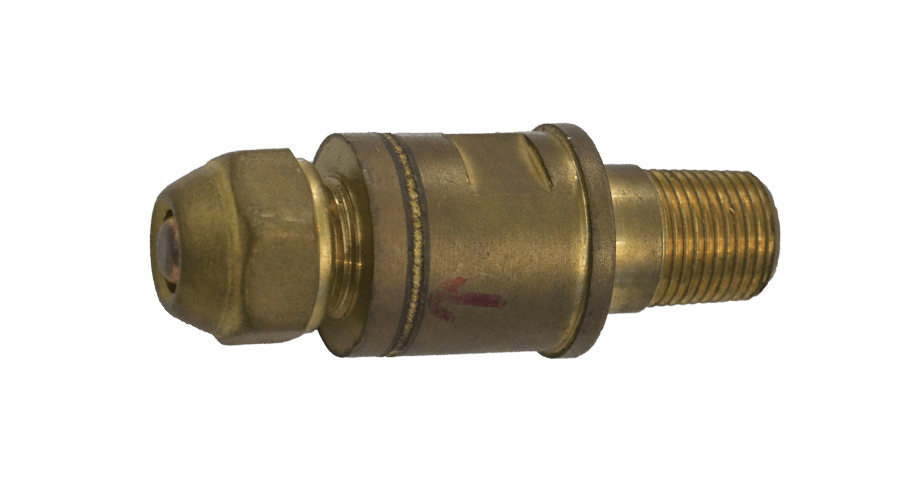

Application and Samples

- Can be used on titanium, nickel, tin, zinc, copper, aluminum, chromium, niobium, gold, silver and other metals and their alloys, as well as steel

- Welding of the same material of such alloys as felling alloys may also be applied to copper-Nickel, nickel-titanium, copper-titanium, brass-copper

- Low carbon steel - copper and other heterogeneous metal welding

Technical Specs

| Maximum Laser Output Power | 300W |

| Laser Output Pulse Energy | 0.5~70J |

| Laser Power Supply | HPP700A0401 |

| Condenser Cavity | Ceramic Reflective Cavity (entrance) |

| Pump Source | 2 × 6KW Pulse Xenon Lamp |

| Laser Crystal | Φ 8 mm Nd: YAG |

| Pulse Width | 0.3ms ~50ms |

| Pulse Frequency | 1~200Hz |

| Maximum Pulse Current | 350A |

| Power Consumption | 15KW |

| Power Demand | 480V+10%/60Hz/40A |

| Control System | CFCS0401 current feedback |

| Waveform Control Function | It can store 50 sets of waveform data, each set can be divided into 16 sections |

| Software | CFCS1.0 |

| Water Cooling System | 3-piece all-in-one chiller or 2-piece split chiller |

| Stroke of Two-dimensional Table for Placing Molds | 100mm×100mm (industrial rocker control) |

| Optional | WJX125 Rotary Table |

| Chuck Diameter | Φ 125 mm |

| Round Beating | 0.08 mm |

| Repeated Positioning Accuracy of Two-dimensional Table | 0.04mm |

| Loading Capacity of Worktable | 300KG |

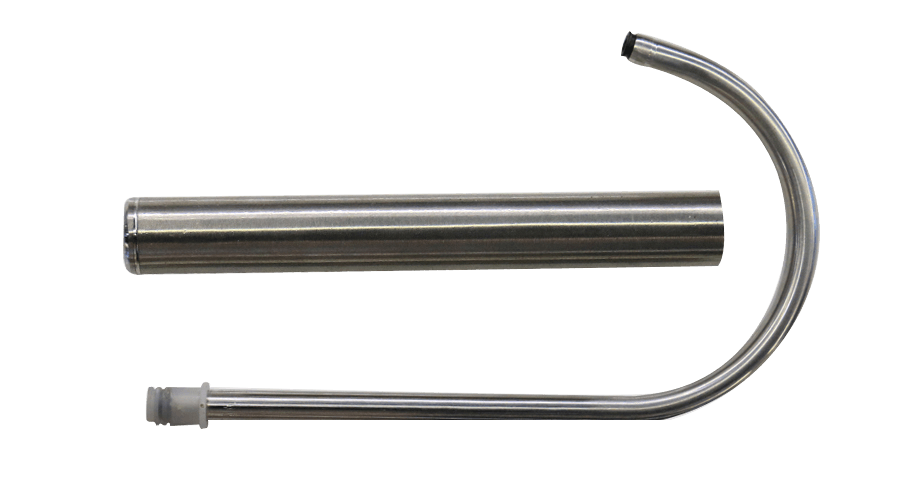

Options and Accessories

We have mature options and accessories to fit your specific application. A custom solution is always welcomed to consult.

ABOUT HAN'S LASER CORPORATION

Han's Laser Corporation is a wholly-owned subsidiary of Han's Laser Technology Group, a global industrial laser technology leader.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

CLIENTS