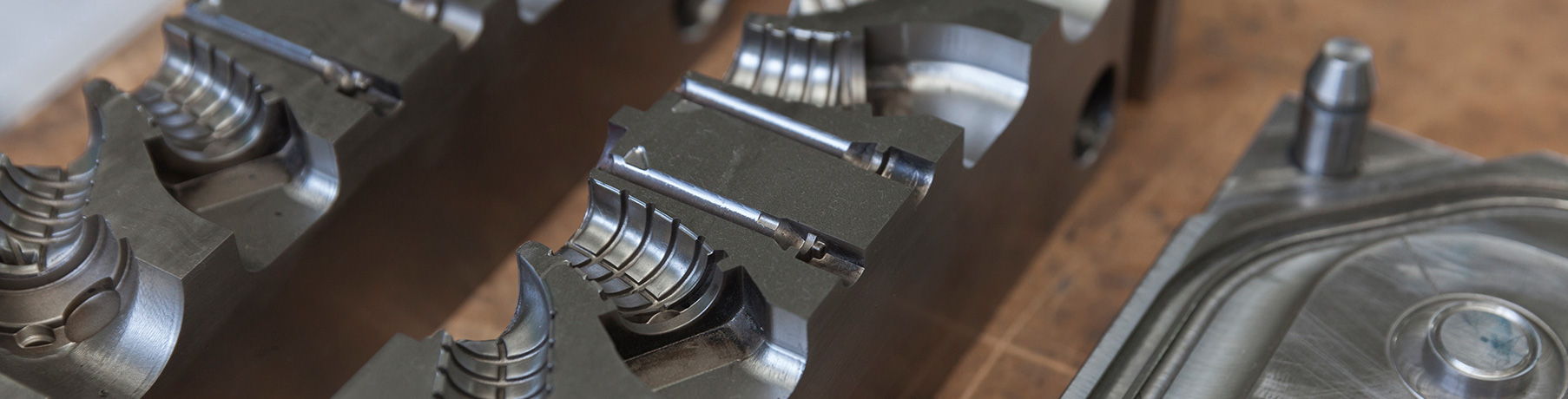

Mold Repairing by Laser

The laser mold repairing machine is a welding technology that uses laser deposition welding to laser high heat energy and concentrates on fixed points, which can effectively handle all minor parts of welding and repair work. The above process is that the conventional argon gas welding and cold welding technology cannot be held exceptionally well in repairing the fine surface of the welding.

The laser mold welding machine can weld all kinds of metal steel, such as 718, 2344, NAK80, 8407, P20, stainless steel, beryllium copper, aluminum alloy, titanium alloy, etc. There are no blisters, pores, collapse and deformation after welding. The bonding strength is high, the welding is firm, and it is not easy to fall off.

Mold Engraving / Marking by Laser

The laser engraving information on the mold can withstand high temperature, corrosion resistance, wear resistance, etc. The engraving speed is fast, and the engraving quality is super fine.

Laser Welder Mold 301 / Mold 302

Laser Welder W150G

Mold Engraving and Marking Machines

Fiber Laser Marking Machine G20

Other Laser Cutting Machines

Laser Cutting Machine

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.