Contact us

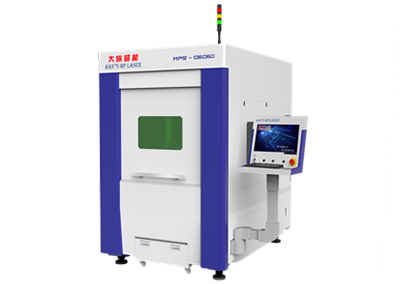

MPS0606D Fiber Laser Precision Cutting Machine

A large fully enclosed cutting area is a standard safety feature on the MPS0606D. Mainly used for cutting carbon steel, stainless, aluminum, titanium, galvanized, brass, copper and other small sheet metal materials. Equipped with a CCD camera vision system, precise positioning and cutting can be achieved to satisfy your customer’s needs.

Primary applications include eyeglass frame processing, electronic accessories and devices, instrumentation, gold and silver jewelry, lighting, sign and advertising industry satisfying many other precision metal cutting needs.

Contact us

Primary applications include eyeglass frame processing, electronic accessories and devices, instrumentation, gold and silver jewelry, lighting, sign and advertising industry satisfying many other precision metal cutting needs.

Features

> Full enclosure with protective observation window offers up the ultimate in safety against laser radiation.

> Easy CCD programming process and operation.

> A real-time display monitor system is safer and more convenient for operation.

> The laser cutting machine comes with a standard 24" x 24" working table to fit the appropriate size sheet metal cutting.

> Focal position is automatically adjusted during the cutting process to achieve the best cutting effect on different thicknesses sheets metal.

> Intelligent alarm system. The working status condition is under monitoring, easy to inspect on the interface. Precaution in advance help to reduce the potential risk, which help to improve the equipment troubleshooting efficiency.

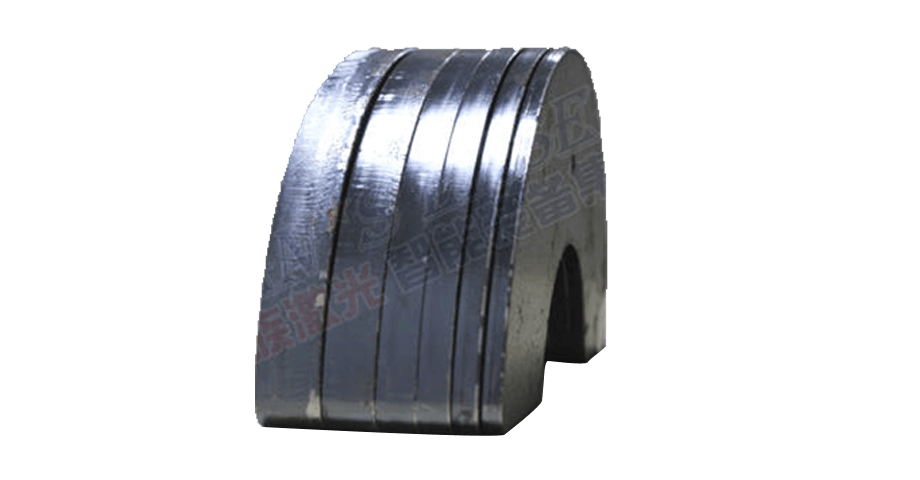

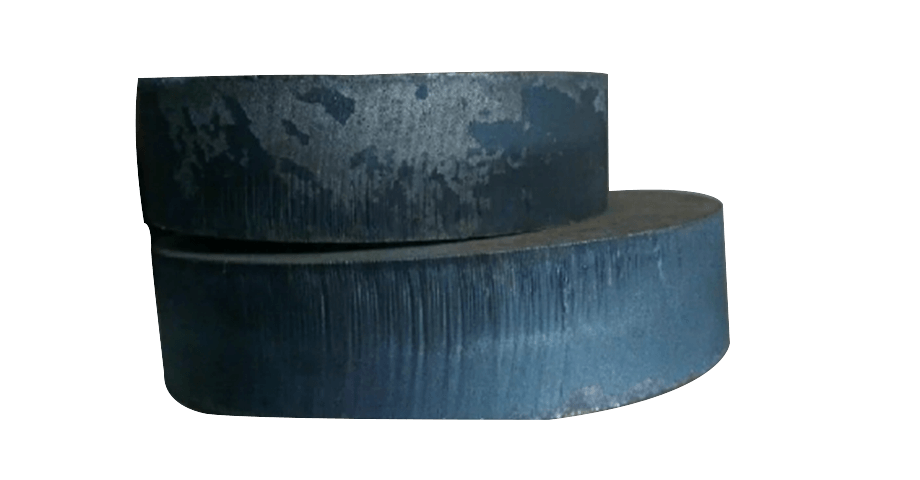

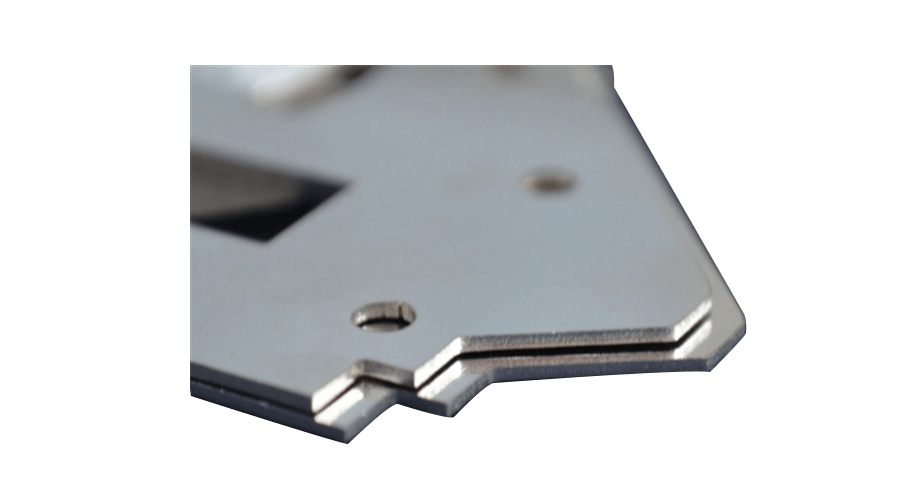

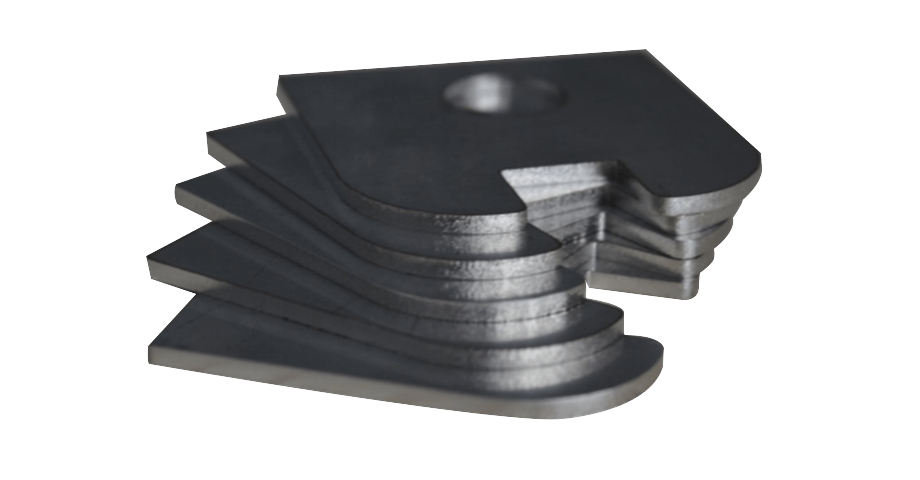

Application and Samples

Applications primarily suited for Optical frame processing, hardware accessories, electronic devices, instrumentation, gold and silver jewelry industry, lighting industry, advertising industry and other metal precision cutting

Technical Specs

| Model | MPS0606D |

| Processing Area | 23.62" x 23.62"(600mm × 600mm) |

| Z-Axis Travel | 3.93"(100mm) |

| Laser Source | IPG |

| Laser Type | Fiber Laser |

| Laser Power | 500, 700 or 1000 Watts Fiber |

| Transmission System | Dual-servo Motor Driving |

| Lubrication System | Automatic Lubrication(Lubrication reminder available) |

| Max Speed | 30m/min |

| Max Acceleration Speed | 0.3G |

| Positioning Accuracy | ±0.03mm |

| Repeat Positioning Accuracy | ±0.02mm |

| Supported Graphics | CAD,DXF etc. |

| Working Environment | 0-40℃ Humidity ≤ 80%, no condensation |

| Max. load of workpiece | 55 lbs (25kg) |

| Power Supply | 3 Phases 380V, /50Hz/60Hz |

| Dimension | 78.74" x 59.05" x 78.74" (2000mm × 1500mm × 2000mm) |

| Weight | 2204 lbs (1000kg) |

Options and Accessories

We have mature options and accessories to fit your specific application. A custom solution is always welcomed to consult.

ABOUT HAN'S LASER CORPORATION

Han's Laser Corporation is a wholly-owned subsidiary of Han's Laser Technology Group, a global industrial laser technology leader.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

CLIENTS