Contact us

Jewelry Laser Spot Welder-W150G

W150G utilizes a laser source that excites Nd: YAG crystal using a pulsed Xenon lamp that resonates to create a laser with a wavelength of 1064 nm.

The whole machine is compact and equipped with a glove box, a microscope coaxial with focus positioning aiming, a liquid crystal light valve and a complete eye protection device to achieve precise positioning. With a laser power real-time feedback control system, based on the preset laser waveform, the system could detect laser power and feedback control the laser source in real-time and adjust the power supply's output current so that laser energy is always stable.

The real-time feedback control system eliminates laser energy instability caused by grid fluctuations, water temperature changes, xenon lamp aging, etc., and improves the consistency of welding products.

Contact us

The whole machine is compact and equipped with a glove box, a microscope coaxial with focus positioning aiming, a liquid crystal light valve and a complete eye protection device to achieve precise positioning. With a laser power real-time feedback control system, based on the preset laser waveform, the system could detect laser power and feedback control the laser source in real-time and adjust the power supply's output current so that laser energy is always stable.

The real-time feedback control system eliminates laser energy instability caused by grid fluctuations, water temperature changes, xenon lamp aging, etc., and improves the consistency of welding products.

Features

- High aspect ratio, thin weld width, minimal heat-affected zone, zero deformation, and fast welding speed

- The weld is smooth and clean, with or without simple process after welding

- High weld strength, no porosity, eliminates the impurities of the base metal, the microstructure can be refined after welding, the weld strength is at least equal to or even exceed the base metal strength

- Tiny laser spot can be precisely positioned and easily automated

- Fit for some dissimilar metal welding

- Spot welding, butt welding, overlap sealing welding

- Various metals such as gold, silver, platinum, stainless steel, titanium, and their alloys

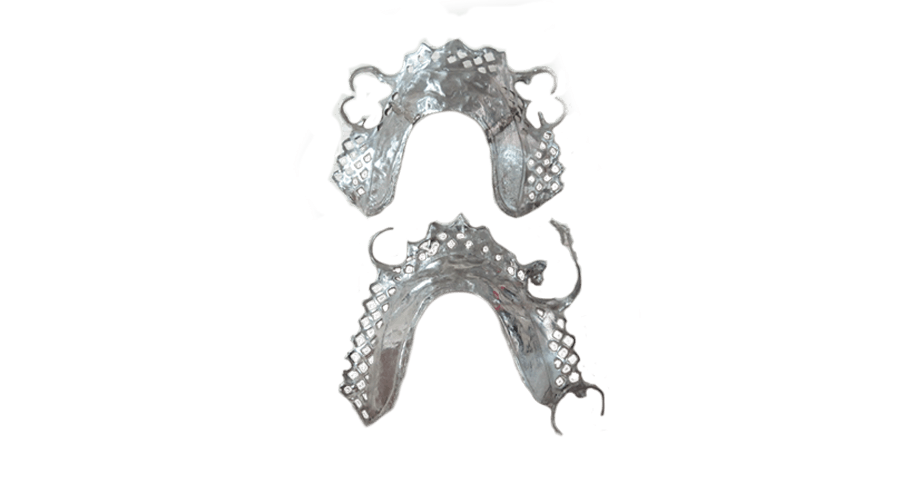

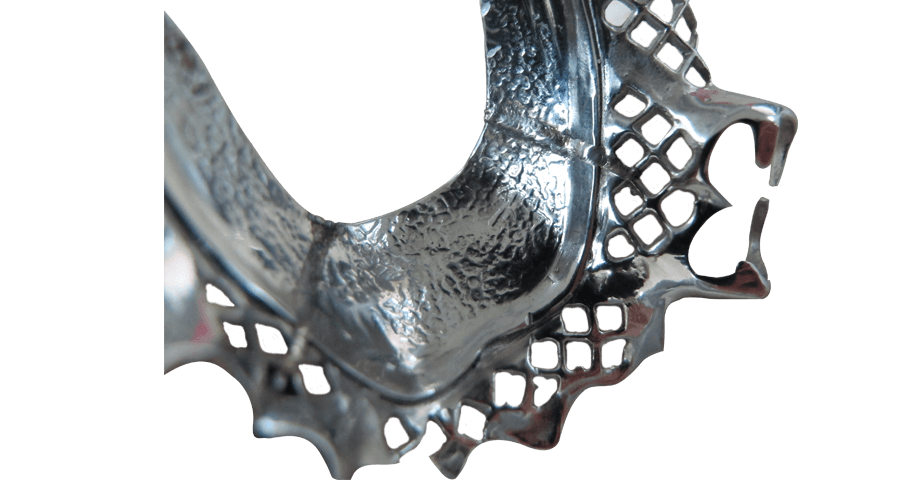

Application and Samples

This laser spot welder is mainly used for repairing holes of gold and silver jewelry, seams, and claw parts. It can be applied to a variety of metals and alloys such as,

- Gold

- Silver

- Platinum

- Stainless steel

- Titanium

Also can be used to repair dentures and other small parts welding such as,

- Battery nickel tape

- Integrated circuit leads,

- Clockspring, picture tube, etc.

The heat-affected zone of the welding process is small, and the spot size is adjustable; Smooth and clean results do not require excessive post-weld treatment.

The laser can be accurately positioned to avoid damaging the jewelry.

Technical Specs

| Model | W150G |

| Laser Type | YAG |

| Wavelength (nm) | 1064 |

| Average Output Power (w) | 150 |

| Pulse Frequency (Hz) | 0~20 |

| Peak Pulse Power (kW) | 9 |

| Maximum Pulse Energy (J) | 80 |

| Pulse Width (ms) | 0.1~20 |

| Cooling System | Air-cooled |

| Laser Welding Molten Pool (mm) | 0.2 |

| Penetration (mm) | 0.1~3 |

| Power Input | 220V (± 10%)20 A, 50/60 Hz |

| Dimensions | 37” L x 9.01” W x 22” H(940mm x 229mm x 559mm) |

| Approx. Weight (unpacked) | 440 lbs (200kg) |

| Warranty Coverage | 1-year |

| Laser Safety Compliance | FDA(CDRH) |

Options and Accessories

3 Axis XYZ worktable

ABOUT HAN'S LASER CORPORATION

Han's Laser Corporation is a wholly-owned subsidiary of Han's Laser Technology Group, a global industrial laser technology leader.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

CLIENTS