Han's Laser provides on-site installation and training plus a two-year warranty.

|

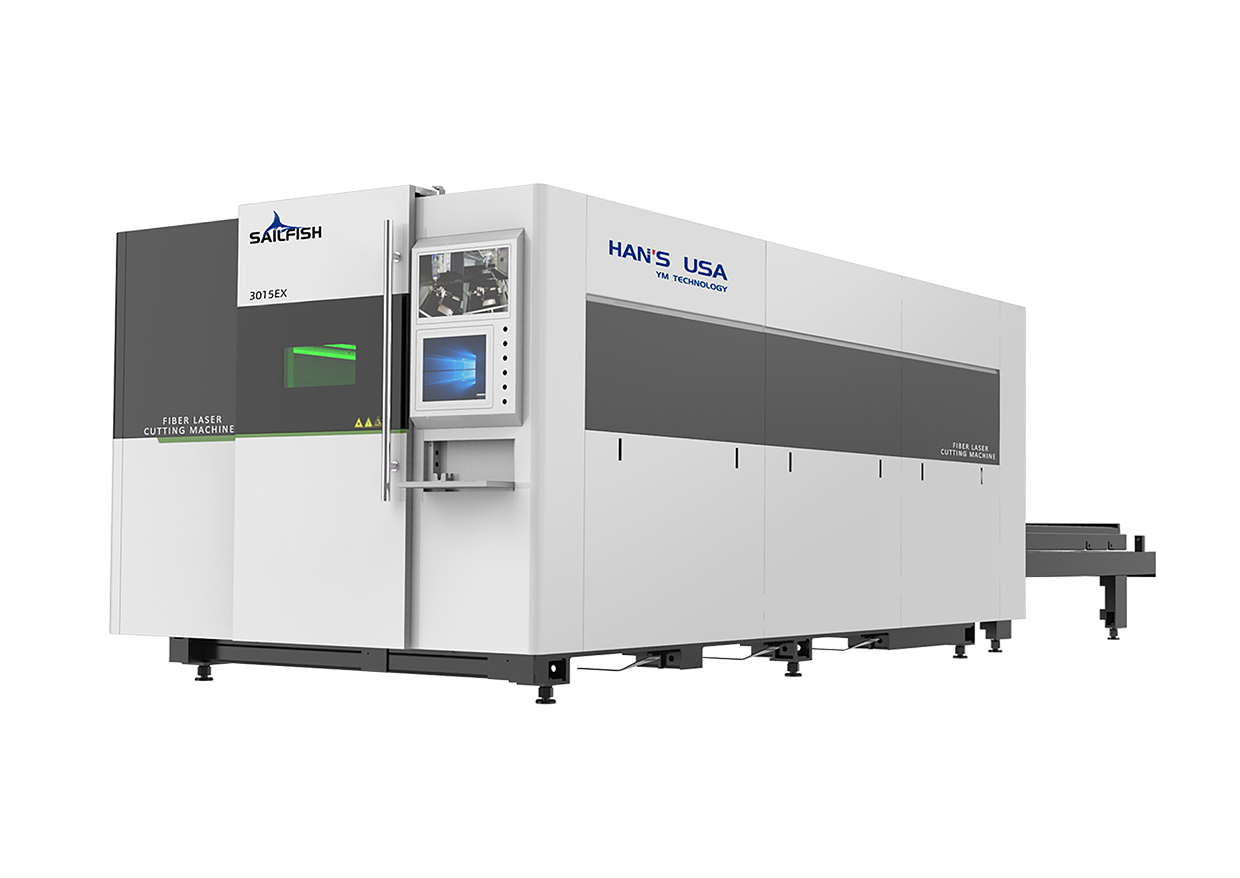

Machine Models |

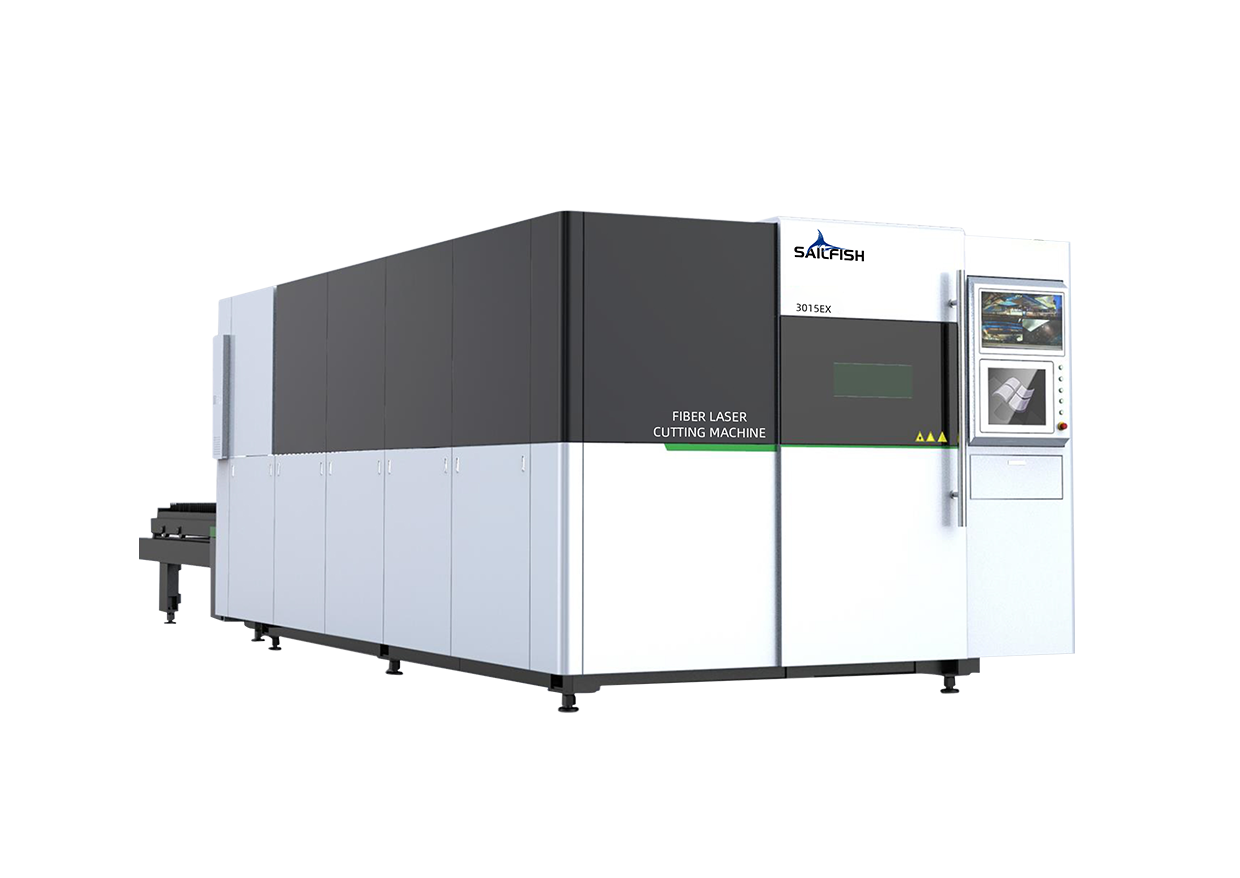

Sailfish 3015 |

Sailfish 4020 |

Sailfish 6020 |

Sailfish 6025 |

|

Working Area |

118.11" x 59.05"(3000mm x 1500 mm) |

157.48" x 78.74" (4000mm x 2000 mm) |

236.22" x 78.74"(6000mm x 2000 mm) |

236.22" x 99.43"(6000mm x 2500 mm)

|

|

Laser Power |

1000, 1500, 2000, 3000, 4000, 6000, 8000, 10000, 120000, 150000 Watts Fiber |

|||

|

Laser Source |

Fiber Laser(IPG) |

|||

|

Working Table |

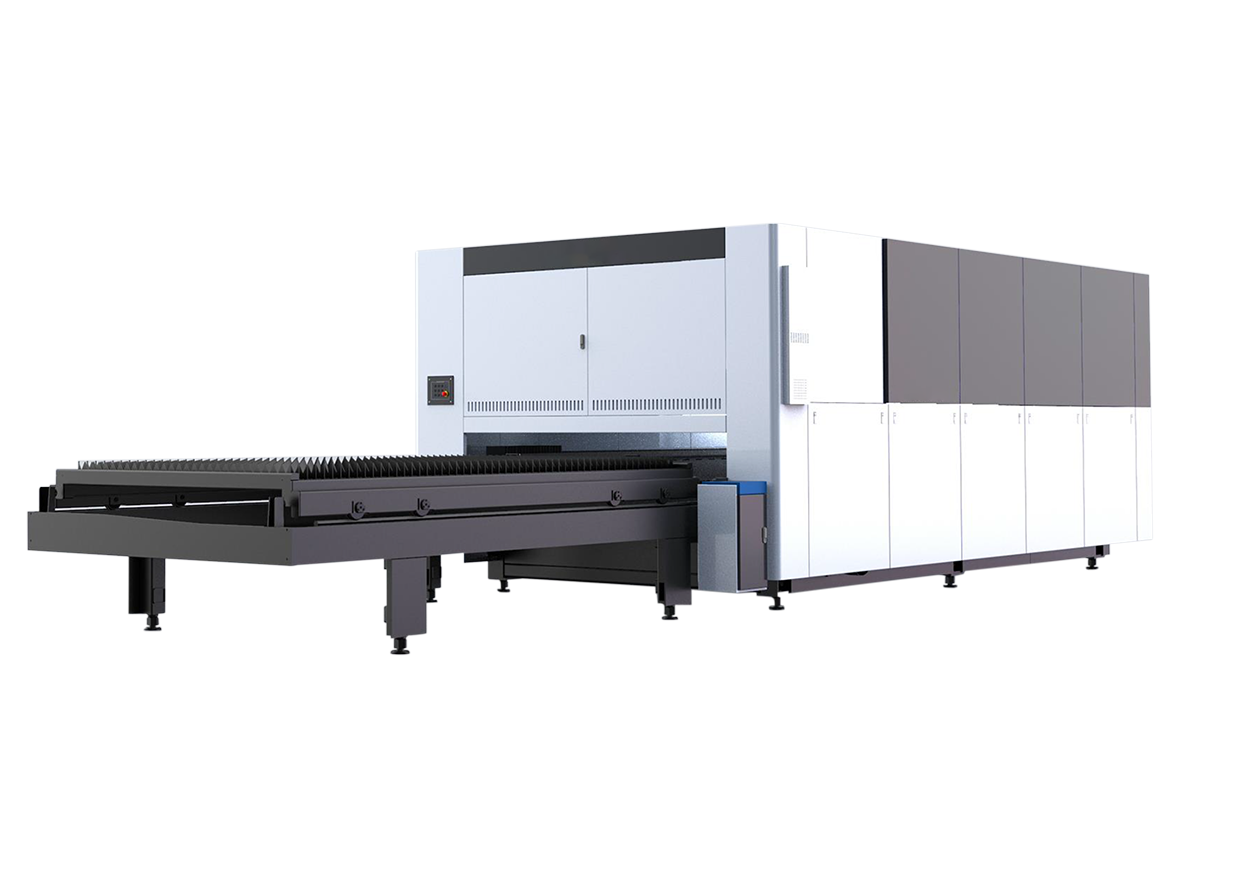

Parallel Exchange Working Table |

|||

|

Loading Method |

Automatic Exchanging Pallets |

|||

|

CNC Controller |

CypCut (Beckhoff Optional) |

|||

|

Drive System |

Motor Power(Italy) |

|||

|

Laser Cutting Head |

RAYTOOLS/PRECITEC |

|||

|

Max Positioning Speed |

140m/min |

|||

|

Maximum Acceleration |

1.4 G |

|||

|

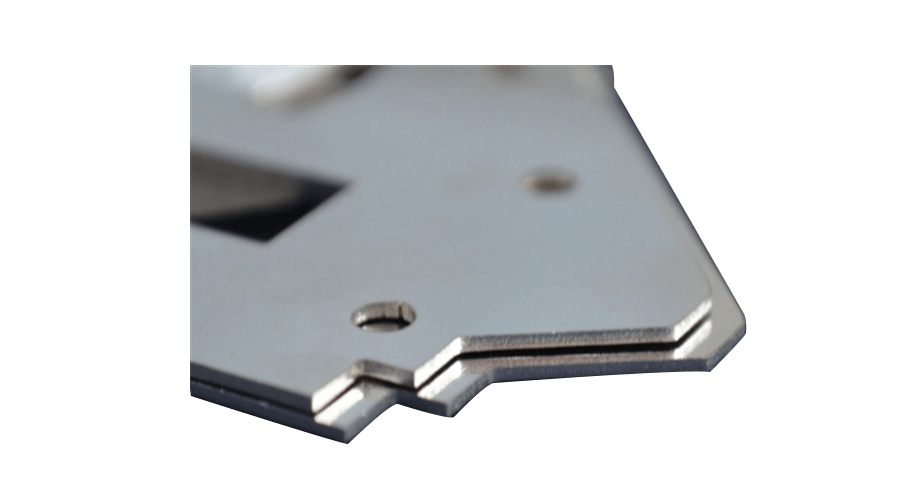

Positioning Accuracy |

± 0.05mm |

|||

|

Repositioning Accuracy |

± 0.03mm |

|||

|

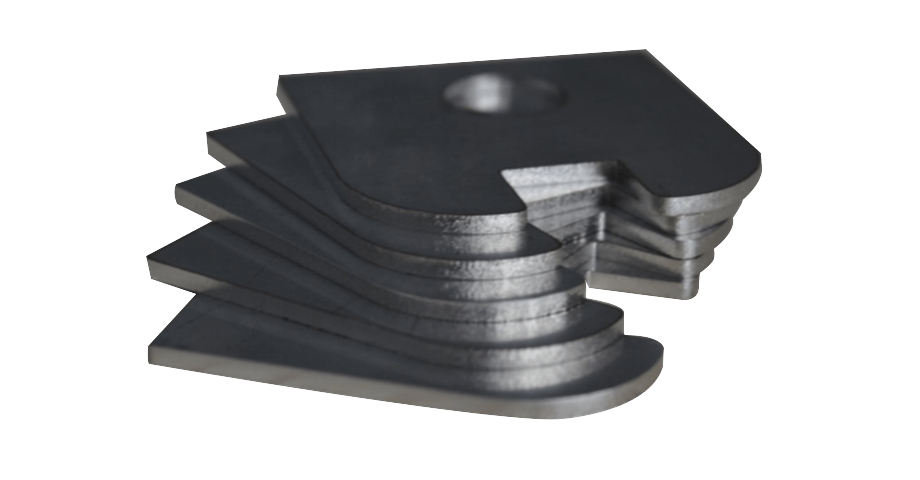

Maximum Workpiece Weight |

1543 lbs (700kg) |

|||

|

Main Machine Power |

10KW |

11KW |

12KW |

|

|

Main Machine Weight |

20943 lbs (9500kg) |

24250 lbs (11000kg) |

26455 lbs (12000kg) |

|

|

Overall Dimension |

350.39"x 118.11" x 80.71" |

472.44" x 141.73" x 80.71" |

610.23" x 165.35" x 80.71" |

|

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.