What is laser soldering? Utilize a laser to fill and melt the tin material to achieve connection, conduction and reinforcement.

Laser is a non-contact processing method. Compared with the traditional way, it has incomparable advantages, good focusing effect, heat concentration, and a minimal thermal impact area around the solder joint, which is conducive to prevent deformation and damage of the structure around the workpiece.

Laser soldering includes pasting laser soldering, wire laser soldering and ball laser soldering. Solder paste, tin wire and solder ball are often used as filler materials in the laser soldering process.

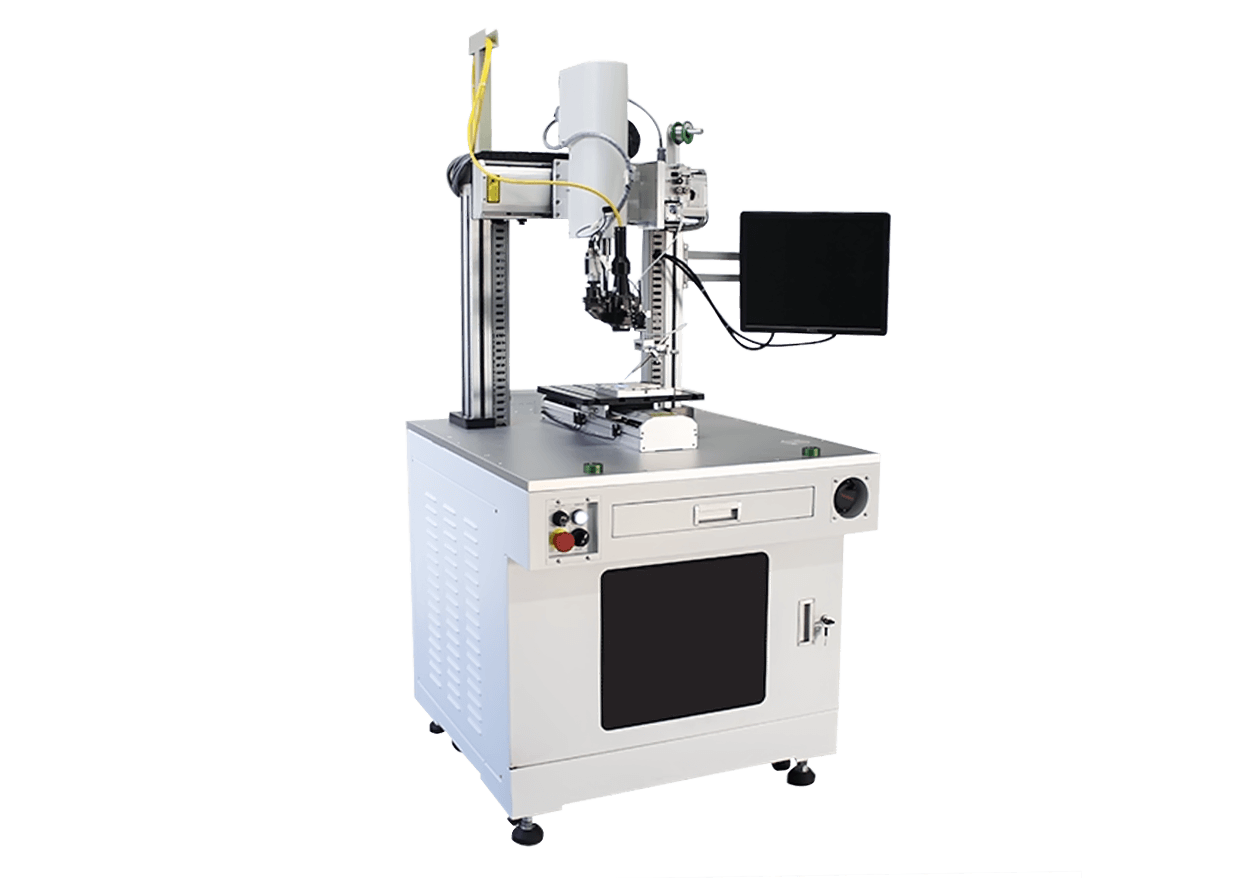

Tin Ball Laser Welding

After being heated and melted by a laser, the solder balls are ejected from the special nozzle and directly cover the pads. No additional flux or other tools are needed. It is very suitable for processing that requires temperature or soft board connection welding area. During the entire process, the solder joints and the welding body are not in contact, which solves the electrostatic threat caused by contact during the welding process.

Compared with traditional technology, laser solder ball welding has the following advantages:

- The laser processing precision is high, the laser spot is small, the program can control the processing time, and the precision is higher than the traditional process method. It is suitable for the soldering of tiny precision parts and the places where the soldering parts are more sensitive to temperature

- Non-contact processing, no static electricity caused by welding, can be processed in conventional ways that are not easy to weld by hand

- A tiny laser beam replaces the soldering iron tip, and it is also easy to process when there are other interfering objects on the surface of the processed part

- Local heating, small heat-affected zone; no electrostatic threat

- Laser is a clean processing method, simple maintenance, convenient operation, and good stability of repeated operation

- The heating speed is fast, and the positioning is accurate, which can be completed in 0.2 seconds

- The tin ball diameter can be as small as 250μm, suitable for high-precision welding

- The yield rate of solder is higher than that of ordinary automatic soldering machines

- With a visual positioning system, it is suitable for assembly line production

Wire Laser Soldering

Tin wire laser welding is suitable for conventional PCB / FPC pin, pad wire and other products with large pad size and open structure. It is challenging to realize the laser welding of thin wire for some points, which are difficult to achieve by wire feeding mechanism and easy to turn around.

Paste Laser Soldering

Solder paste laser welding process is suitable for conventional PCB / FPC pin, pad line and other types of products.

The processing method of solder paste laser welding can be considered if the precision requirement is high and the manual way is challenging to achieve.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.