Contact us

Laser Marking Machine with Electric X, Y Working Table

Fiber laser marking machine with electric X, Y working table.

The vision camera can recognize the fiducial point, which help laser mark parts precisely.

> READ MORE

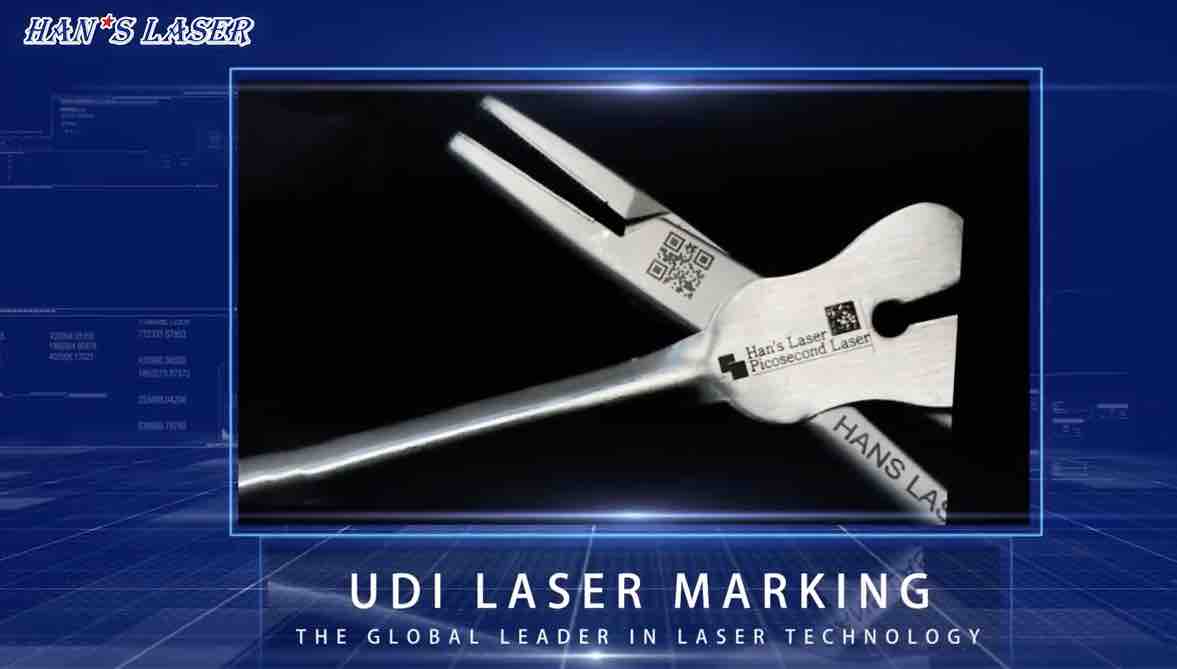

Laser Applications on Medical Industry

Laser plastic welding, Laser cutting, Laser marking, PCB depaneling for medical devices and beyond. Han's Laser can provide a complete solution to meet your unique demand.

> READ MORE

Laser Marking on Thermometer

Laser marking on different kinds of thermometers, including non-contact digital infrared thermometer and other electronic body thermometers.

> READ MORE

Inline PCB laser depaneling machine

Inline PCB laser depaneling machine.

400mm x 300mm working area.

20W UV laser, 40W Green laser for FPCB, rigid PCB laser cutting.

> READ MORE

ABOUT HAN'S LASER CORPORATION

Han's Laser Corporation is a wholly-owned subsidiary of Han's Laser Technology Group, a global industrial laser technology leader.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

CLIENTS