Han's Laser Micro Processing: Micro Laser Holes

Generally, the holes processed by the scanning galvanometer are all positive tapers, and it is challenging to realize the processing of different taper holes and shaped holes cause the failure to control the touching angle. Widely used long-pulse laser processing has a large heat-affected zone which would get recast layers.

Han’s Laser did deep researches and now launch the "multi-axis ultra-fast micro-machining equipment" HN-GY-PS60, which can not only realize X, Y, Z motion control in three directions and also possible to rea-time control the rotation of the laser beam and the laser touching angle. We also provide assistance options such as coaxial observation camera, fume extractor, and real-time power monitoring system, etc., to help customers manage the process. The customer can realize the drilling and cutting of various holes such as cylindrical holes, positive tapered holes, negative tapered holes, and square holes by any combination of processing parameters.

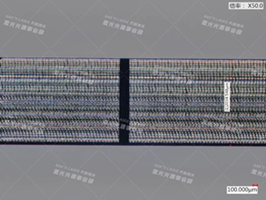

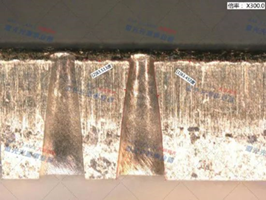

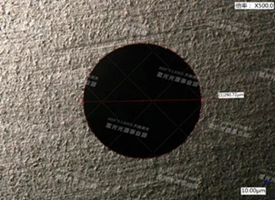

1.1 Straight hole (Cross section)

|

Material: 2mm Stainless steel

Diameter:220um Taper:0° Aspect ratio:9:1 |

Material:2.3mm Boron nitride

Diameter:230um Taper:0° Aspect ratio:10:1 |

Top view Cross section 500x

|

|

Material:0.3mm Stainless Steel

Diameter:290/153um Taper:+14° |

1.3 Negative taper hole

Top view Cross section 300x

|

|

Material:0.5mm copper |

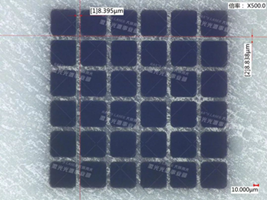

2.Shaped holes

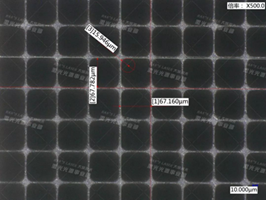

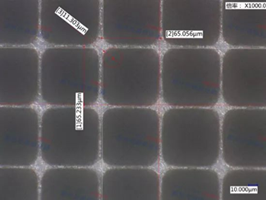

2.1 Squared holes

Material: 1mm Alumina

Size: 58*58um

Internal distance:9um

Chamfer:7um

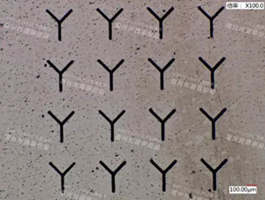

2.2 Y-shaped holes

Top Bottom 500x

|

|

Material:0.1mm stainless steel |

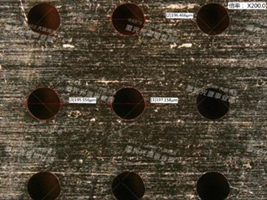

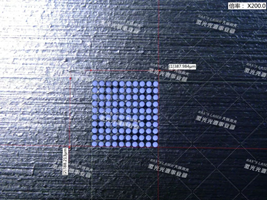

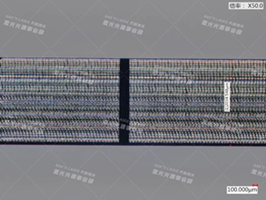

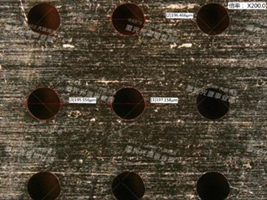

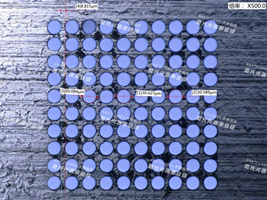

3. Holes in array

300X 1000X

Material: 0.1 Silicon steel

Range 0.4*0.4mm

Numbers: 100

Diameter:30um

Internal distance:10um

Taper:0°

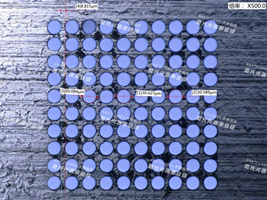

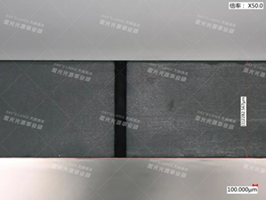

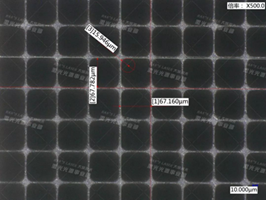

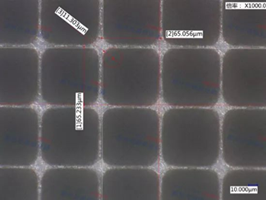

3.1 Squared blind holes array

300X 1000X

Material:2.3mm Boron nitride

Size of the hole:65*65um

Chamfer:11um

Internal distance:6um

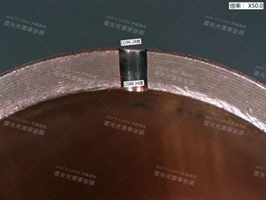

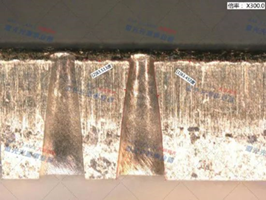

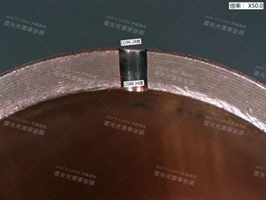

4.

Top 50x Cross section

Diameter of the hole:650um

Taper:0°

Features

- The software offers the multi-dimensional parameters to form the machining path for any irregular shape and any taper drilling applications

- Realize the surface roughness of the inner wall Ra<0.1μm

- Equipped with coaxial high-pressure air blowing device and annular fume extractor device to minimize the slagging

- High precision linear motion platform with repeatability of ±0.002 mm

- Optional coaxial camera system for real-time monitoring module

Application field

"Multi-axis ultra-fast micro-machining equipment" can realize the processing of various types of microstructures of various metals, non-metals and composite materials, such as automotive injectors, aerospace turbine blade film holes, semiconductor probes and high-end watch gears.

Generally, the holes processed by the scanning galvanometer are all positive tapers, and it is challenging to realize the processing of different taper holes and shaped holes cause the failure to control the touching angle. Widely used long-pulse laser processing has a large heat-affected zone which would get recast layers.

Han’s Laser did deep researches and now launch the "multi-axis ultra-fast micro-machining equipment" HN-GY-PS60, which can not only realize X, Y, Z motion control in three directions and also possible to rea-time control the rotation of the laser beam and the laser touching angle. We also provide assistance options such as coaxial observation camera, fume extractor, and real-time power monitoring system, etc., to help customers manage the process. The customer can realize the drilling and cutting of various holes such as cylindrical holes, positive tapered holes, negative tapered holes, and square holes by any combination of processing parameters.

1.1 Straight hole (Cross section)

Diameter:220um

Taper:0°

Aspect ratio:9:1

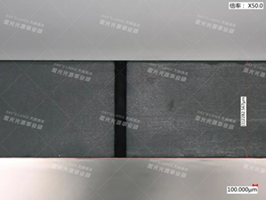

Material:2.3mm Boron nitride

Diameter:230um

Taper:0°

Aspect ratio:10:1

Top view

Cross section 500x

Material:0.3mm Stainless Steel

Diameter:290/153um

Taper:+14°

1.3 Negative taper hole

Top view

Cross section 300x

Material:0.5mm copper

Diameter:107/197μm

Taper: -6.5°

2.Shaped holes

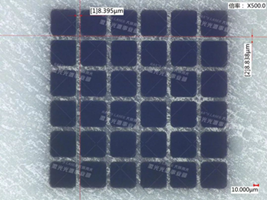

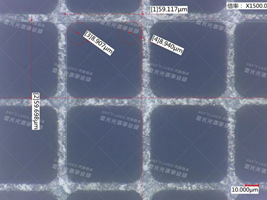

2.1 Squared holes

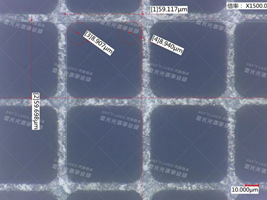

Cross section 500x

Cross section 1500x

Material: 1mm Alumina

Size: 58*58um

Internal distance:9um

Chamfer:7um

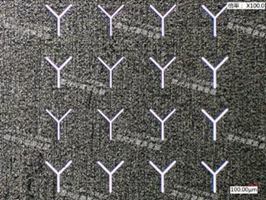

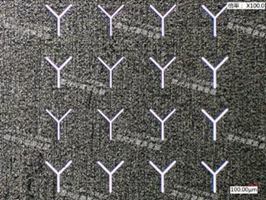

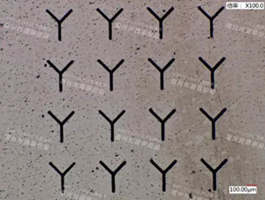

2.2 Y-shaped holes

Bottom

500x

Material:0.1mm stainless steel

Width:26μm

Taper: 0°

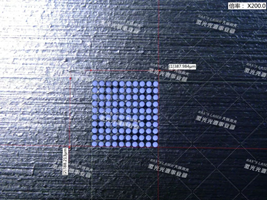

3. Holes in array

1000X

Range 0.4*0.4mm

Numbers: 100

Diameter:30um

Internal distance:10um

Taper:0°

3.1 Squared blind holes array

300X

1000X

Material:2.3mm Boron nitride

Size of the hole:65*65um

Chamfer:11um

Internal distance:6um

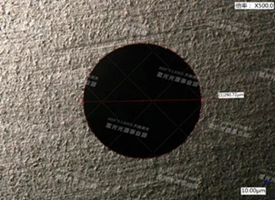

4.Drilling on curved surface

Top

50x Cross section

Diameter of the hole:650um

Taper:0°

- The software offers the multi-dimensional parameters to form the machining path for any irregular shape and any taper drilling applications.

- Realize the surface roughness of the inner wall Ra<0.1μm.

- Equipped with coaxial high-pressure air blowing device and annular fume extractor device to minimize the slagging.

- High precision linear motion platform with repeatability of ±0.002 mm.

- Optional coaxial camera system for real-time monitoring module.

Application field

"Multi-axis ultra-fast micro-machining equipment" can realize the processing of various types of microstructures of various metals, non-metals and composite materials, such as automotive injectors, aerospace turbine blade film holes, semiconductor probes and high-end watch gears.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.