Contact us

Laser technology subverts the traditional technology of the camera glass cover

2019-09-27

121 times

At 1 a.m. Beijing time on September 11, Apple's new product launch was held at the Apple Park Jobs Theatre in Cupertino, California.

In this year's Apple Autumn Conference, Apple introduced the new iphone11 series, namely iPhone 11, iPhone 11 Pro and iPhone 11 ProMax.

From the news disclosed in the live video of the Apple conference, the camera is the biggest upgrade point. Although iphone11 is still two cameras, the original wide-angle + telephoto combination has become a wide-angle + super wide-angle combination; iphone11Pro and iPhone 11 Pro Max have adopted telephoto + wide-angle + super wide-angle three camera design.

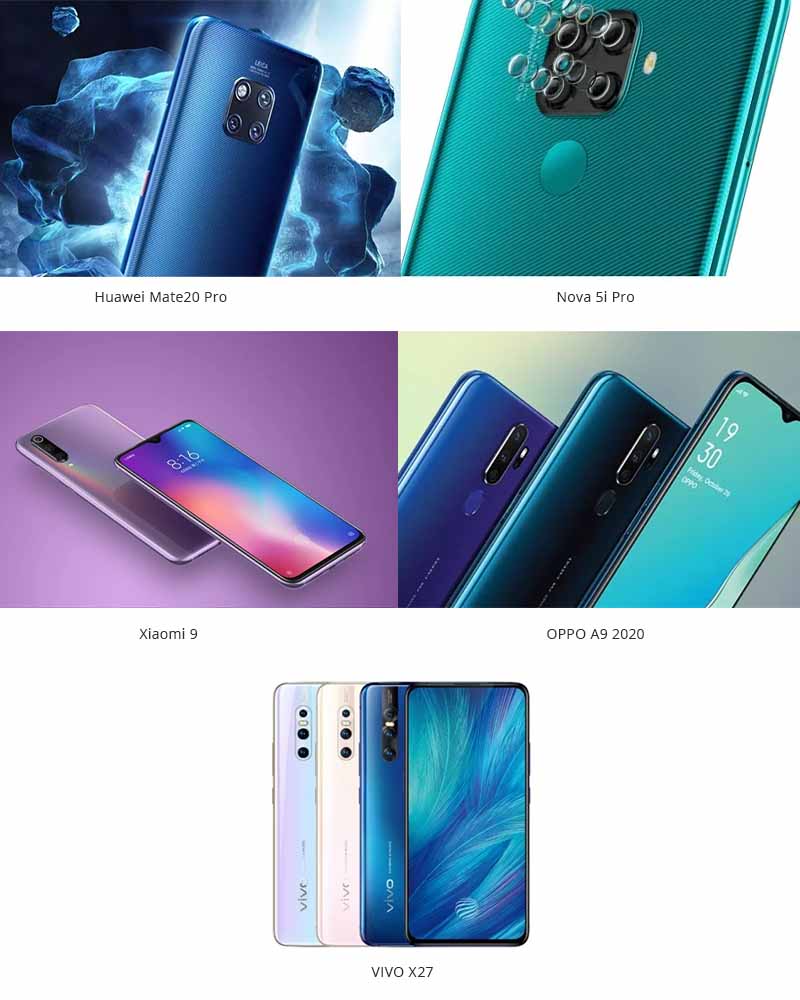

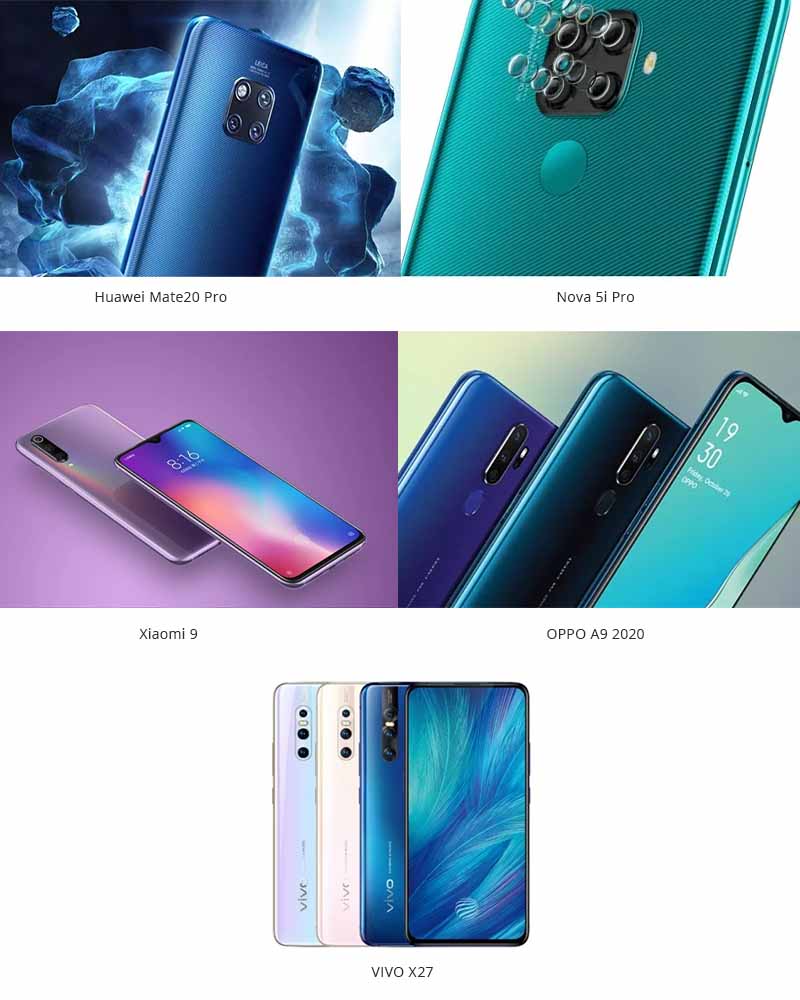

For this Android camp has been prepared, the domestic "four big": Huawei, Xiaomi, OPPO, Vivo in the new mobile phone launched this year, the camera performance has significantly improved.

For example,

(picture from the network)

In this year's Apple Autumn Conference, Apple introduced the new iphone11 series, namely iPhone 11, iPhone 11 Pro and iPhone 11 ProMax.

From the news disclosed in the live video of the Apple conference, the camera is the biggest upgrade point. Although iphone11 is still two cameras, the original wide-angle + telephoto combination has become a wide-angle + super wide-angle combination; iphone11Pro and iPhone 11 Pro Max have adopted telephoto + wide-angle + super wide-angle three camera design.

For this Android camp has been prepared, the domestic "four big": Huawei, Xiaomi, OPPO, Vivo in the new mobile phone launched this year, the camera performance has significantly improved.

For example,

(picture from the network)

The camera cover is from a single camera to double cameras to three cameras. The size of the cover plate is getting bigger and bigger, and the shape is also various. The traditional machining process is a small piece process: cutter wheel + CNC (single grain) + reinforced (single grain) + silkscreen, each station requires a lot of manpower, low processing efficiency (double head CNC machining double-shot runway UPH = 400 granules/ h) and easy to scratch the product, the straight-through yield is low.

According to statistics, in 2018, the global smartphone shipments were 1.42 billion, and the main manufacturers were Samsung, Apple, Huawei, Xiaomi, Oppo, Vivo, Lenovo, ZTE, and LG. In addition to the high-end models, the camera cover is made of sapphire material of about 400 million pieces, and the remaining 1 billion pieces are made of tempered glass.

Faced with such huge market demand, the traditional process of the cover industry is in urgent need of upgrading. In this context, Han's Lase has developed a large-plate process with industry customers: cutter wheel cutting (middle film) + laser cutting + corrosion (medium film) + strengthening (medium film) ) + full-screen printing + unload film. The new process saves a lot of labor costs, greatly increases production capacity and yield, and reduces operating costs for industry customers. At present, Han’s Laser’s cutting equipment has been verified by customers in more than 30 industries across the country and has been shipped in batches. Some customers have been mass-produced for nearly half a year.

The new process core station - laser cutting, the equipment uses the independently developed Micro-cut (Draco infrared picosecond + cutting head) cutting technology from laser light source division, which is suitable for glass such as 0.05-0.8mm Corning, Schott, Asahi Glass, Panda, Sodium Calcium and sapphire shaped cutting. Take the 0.4mm Corning 5th generation glass cutting 24 track camera cover as an example, the UPH can be as high as 2,700 granules/h, and the daily capacity is 60K/set, which is more than 6 times that of the double-head CNC.

According to statistics, in 2018, the global smartphone shipments were 1.42 billion, and the main manufacturers were Samsung, Apple, Huawei, Xiaomi, Oppo, Vivo, Lenovo, ZTE, and LG. In addition to the high-end models, the camera cover is made of sapphire material of about 400 million pieces, and the remaining 1 billion pieces are made of tempered glass.

Faced with such huge market demand, the traditional process of the cover industry is in urgent need of upgrading. In this context, Han's Lase has developed a large-plate process with industry customers: cutter wheel cutting (middle film) + laser cutting + corrosion (medium film) + strengthening (medium film) ) + full-screen printing + unload film. The new process saves a lot of labor costs, greatly increases production capacity and yield, and reduces operating costs for industry customers. At present, Han’s Laser’s cutting equipment has been verified by customers in more than 30 industries across the country and has been shipped in batches. Some customers have been mass-produced for nearly half a year.

The new process core station - laser cutting, the equipment uses the independently developed Micro-cut (Draco infrared picosecond + cutting head) cutting technology from laser light source division, which is suitable for glass such as 0.05-0.8mm Corning, Schott, Asahi Glass, Panda, Sodium Calcium and sapphire shaped cutting. Take the 0.4mm Corning 5th generation glass cutting 24 track camera cover as an example, the UPH can be as high as 2,700 granules/h, and the daily capacity is 60K/set, which is more than 6 times that of the double-head CNC.

ABOUT HAN'S LASER CORPORATION

Han's Laser Corporation is a wholly-owned subsidiary of Han's Laser Technology Group, a global industrial laser technology leader.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

CLIENTS