|

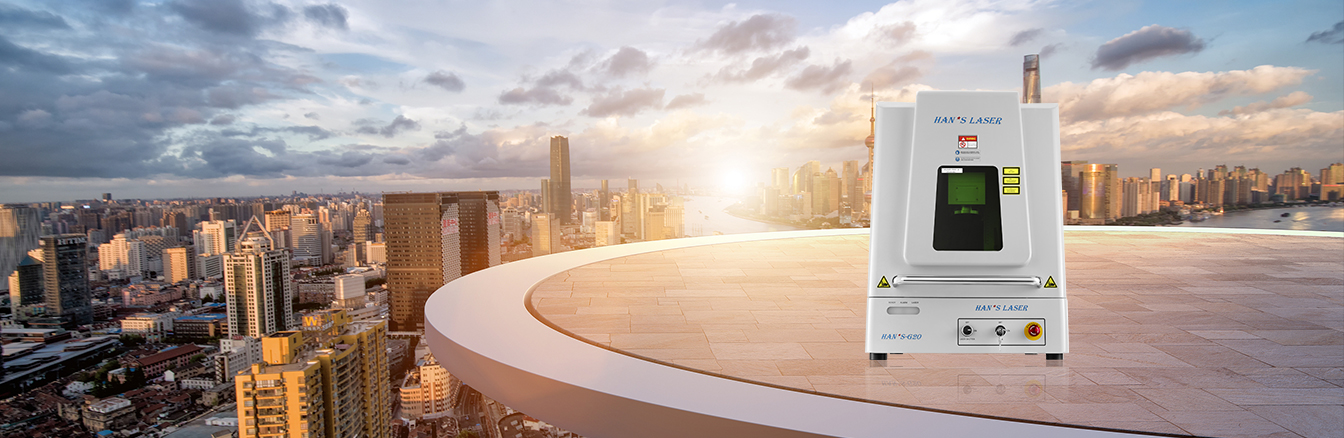

FLY3015 Fiber Laser Cutting Machine

A large 120"x60" fully enclosed cutting area is a standard safety feature on the FLY3015. The in-line exchange worktable makes it easy to cut up to 25mm carbon steel and 15mm stainless steel in addition to aluminum, brass, copper, titanium and other non-ferrous metals. Han’s Laser provides on-site installation, training plus a one-year warranty.

The FLY3015 is recommended for cutting various sheet metal products in metal fabrication industries, such as agricultural machinery, automotive, aircraft ships, electronics, lighting, sign industry, elevator manufacturing,household electrical appliances, etc.

Features +Full enclosure with protective observation window offers up the ultimate in safety against stray radiation. +Fiber offers reduced maintenance requirements and operating costs compared to CO2 Laser machines. +Video monitoring system is installed in the cutting area, and the cutting situation can be observed in real time through the display screen, which is more safe and convenient. +Cutter working table comes standard with 120" x60". Working table extends 240" x80" (optional)accepting full sheets of metal. +Focal point will be automatically adjusted in cutting process to achieve the best cutting effect of different thicknesses sheets metal.Applicable to various focal lengths, which are controlled by machine control system. +Automatic lubrication system provides timing and ration lubricating oil for equipment to ensure its normal and high speed operation, and owns functions of abnormal alarm and liquid level alarm. The system greatly enhances cutting accuracy and effectively extends service life of transmission mechanism. +Intelligent alarm system,The system will start full abnormal alarm and push it to the interface through control center when equipment is abnormal. Finding equipment abnormal in advance and reducing hidden dangers can multiply improve the equipment trouble. |

|

FLY3015 Fiber Laser Cutting Machine

A large 120"x60" fully enclosed cutting area is a standard safety feature on the FLY3015. The in-line exchange worktable makes it easy to cut up to 25mm carbon steel and 15mm stainless steel in addition to aluminum, brass, copper, titanium and other non-ferrous metals. Han’s Laser provides on-site installation, training plus a one-year warranty.

The FLY3015 is recommended for cutting various sheet metal products in metal fabrication industries, such as agricultural machinery, automotive, aircraft ships, electronics, lighting, sign industry, elevator manufacturing,household electrical appliances, etc.

Features +Full enclosure with protective observation window offers up the ultimate in safety against stray radiation. +Fiber offers reduced maintenance requirements and operating costs compared to CO2 Laser machines. +Video monitoring system is installed in the cutting area, and the cutting situation can be observed in real time through the display screen, which is more safe and convenient. +Cutter working table comes standard with 120" x60". Working table extends 240" x80" (optional)accepting full sheets of metal. +Focal point will be automatically adjusted in cutting process to achieve the best cutting effect of different thicknesses sheets metal.Applicable to various focal lengths, which are controlled by machine control system. +Automatic lubrication system provides timing and ration lubricating oil for equipment to ensure its normal and high speed operation, and owns functions of abnormal alarm and liquid level alarm. The system greatly enhances cutting accuracy and effectively extends service life of transmission mechanism. +Intelligent alarm system,The system will start full abnormal alarm and push it to the interface through control center when equipment is abnormal. Finding equipment abnormal in advance and reducing hidden dangers can multiply improve the equipment trouble. |

Application and Samples

Applications primarily suited for sheet metal processing,such as various metal products processing industries,agricultural machinery industry ,automobiles, aircraft and ships,electrical equipment,lighting advertising industry,elevator manufacturing,kitchen electrical appliances and so on.

Technical Specs

| Machine Models | FLY 3015 | FLY 4020 | FLY 6020 |

| Working area |

120" x60" (3000mm x 1500 mm) |

160" x80" (4000mm x 2000 mm) |

240" x80" (6000mm x 2000 mm) |

| Laser power | 1000W/1500W/2000W/3000W4000W(optional) | ||

| Laser source | Fiber Laser(IPG) | ||

| Working table | Parallel exchange working table | ||

| Loading method | Manual | ||

| CNC controller | CypCut (Beckhoff optional) | ||

| Drive system | Synchronized dual large torque servo motor | ||

| Laser cutting head | RAYTOOLS/PRECITEC | ||

| Max positioning speed | 460 ft/min (140 m/min) | ||

| Maximum acceleration | 1.5 G | ||

| Positioning accuracy | ± 0.002"(± 0.05mm) | ||

| Repositioning accuracy | ± 0.0012"(± 0.03mm) | ||

| Maximum workpiece weight | 1540 lbs(700Kg) | ||

| Main machine power | 10KW | 11KW | 12KW |

| Main machine weight | 20900 lbs(9500Kg) | 20900 lbs(11000Kg) | 29700 lbs(12000Kg) |

| Overall dimension |

(8900x3000x2100mm) 1356" x120"x84" |

(12000x3600x2100mm) 480" x144"x84" |

(15500x4200x2200mm) 620" x168"x88" |