Contact us

Laser Depaneling PCBA Machine HDZ- UVC3030

Laser de-paneling machine for PCBA and related industry.

A turn-key design. The UV laser depaneling machine is assembled with a state-of-the-art 355nm Draco laser module, with fine-tuning, which ensures consistent, high-quality cutting on the fiberglass material (FR4) and flexible PCBA. The cold working method produces small heat-affected zones(HAZ), minimizes the charring, and makes minimal mechanical and thermal stress, distortion-free.

SW control can quickly process any complex contours, no die cost, equipped with user-friendly software support with a quick parameter setting that produces a clean cut without damaging the substrate and components of the PCBA.

A 2D bar code and serial numbers can be marked with the machine.

Contact us

A turn-key design. The UV laser depaneling machine is assembled with a state-of-the-art 355nm Draco laser module, with fine-tuning, which ensures consistent, high-quality cutting on the fiberglass material (FR4) and flexible PCBA. The cold working method produces small heat-affected zones(HAZ), minimizes the charring, and makes minimal mechanical and thermal stress, distortion-free.

SW control can quickly process any complex contours, no die cost, equipped with user-friendly software support with a quick parameter setting that produces a clean cut without damaging the substrate and components of the PCBA.

A 2D bar code and serial numbers can be marked with the machine.

Features

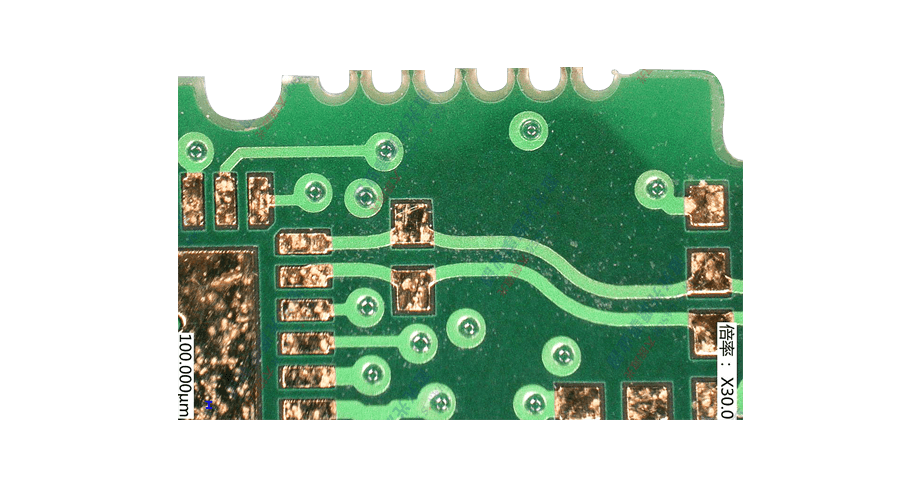

The UV laser is 355 nm wavelength, with a "cold marking" method, the laser beam diameter is only 20 μm after focusing, the UV laser's pulse energy comes in contact with the material in the microsecond. There is no significant thermal influence next to the slit, so no heat damages the electronic component.

UV Laser is suitable for rigid and flexible substrate cutting and marking, like FR4 substrates and imitation resin-based materials, polyimide, ceramics, PTFE, polyester, aluminum, brass, and copper, etc.

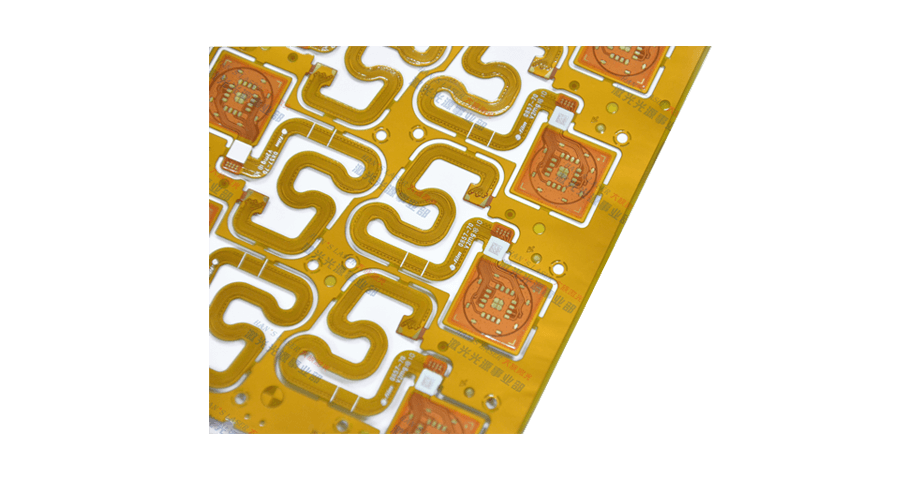

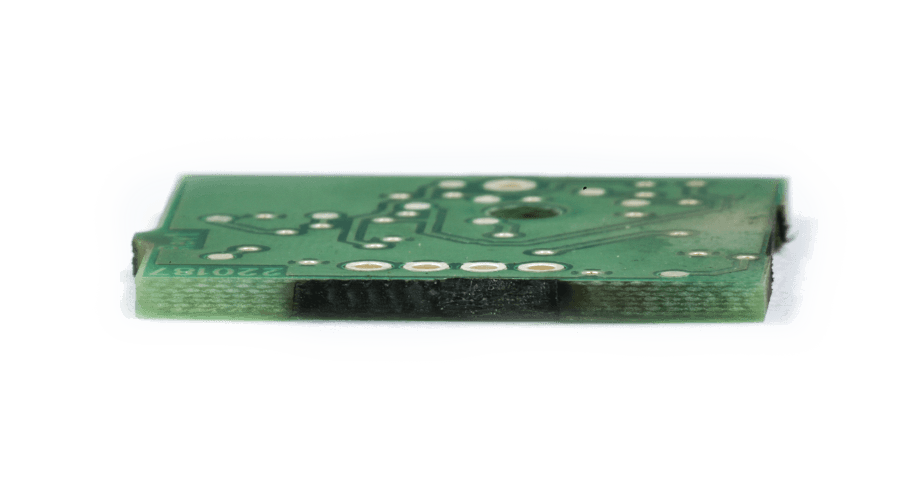

- UV laser processing is non-contact processing, stress-free, and will not deform the board

- It will not produce dust, the cutting edges are smooth and tidy, and there will be no burrs

- PCBA processing is achievable

- Any graphics can be processed by Han's Laser specified software

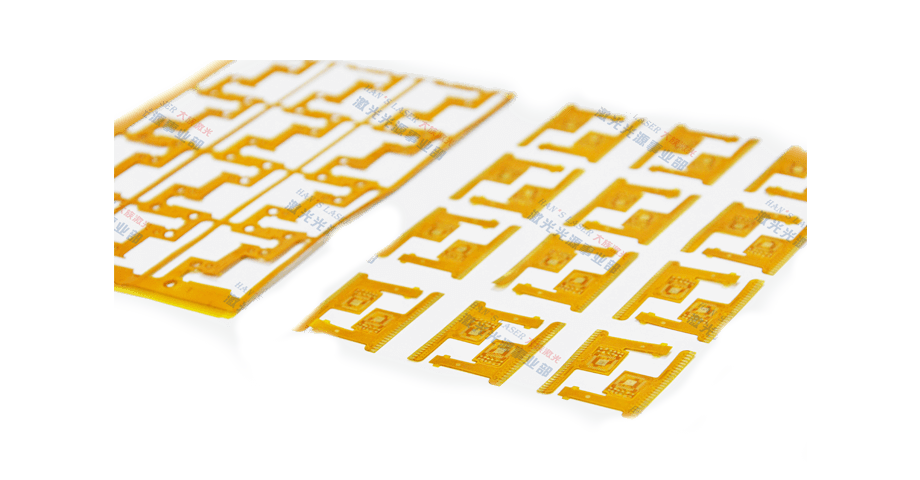

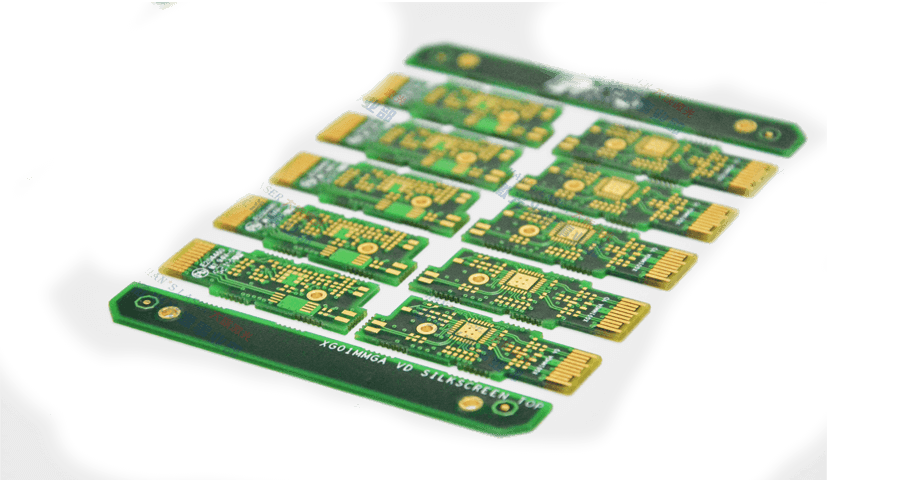

- Capable of making FPC, Rigid printed circuit board laser singulation

- A two-dimensional linear moving stage and high-resolution CCD guarantees high accuracy and precision

- The cutting capacity of the machine is up to 0.004" to 0.07" thickness

- Able to mark 1D, 2D barcode, GS1 code, Series numbers

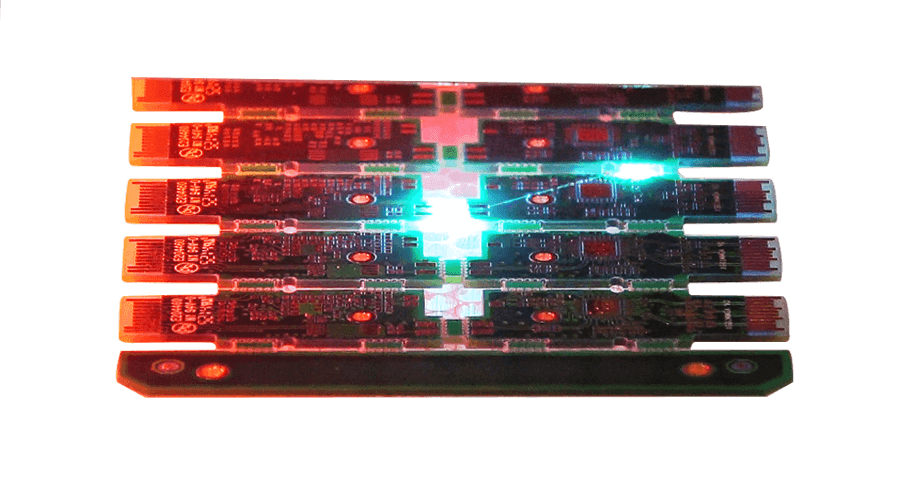

- X-out marking is available as an optional extension

- Selectable working field size and laser power to meet specific demand

- Complies with the SMEMA standard

Click the link below to see our fully automated system design.

Click the link below to see our fully automated system design.

A Fully Automated System of PCBs Laser Depaneling, Sorting and Stacking

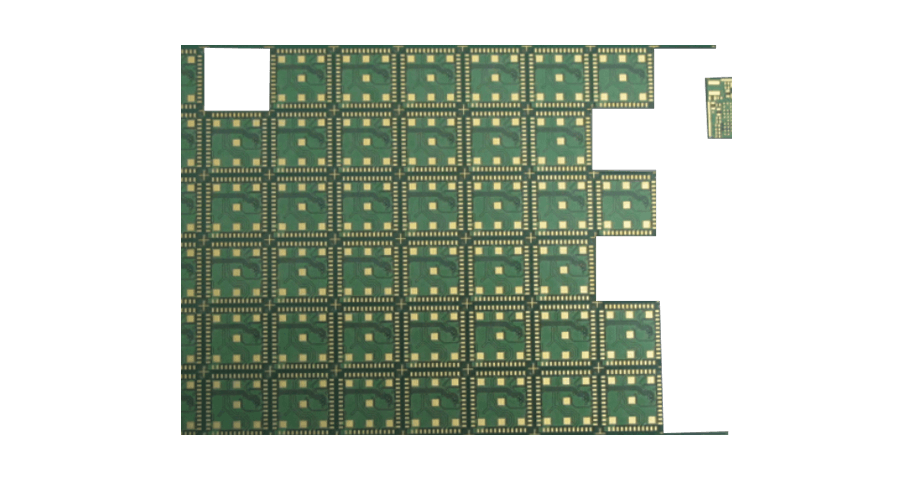

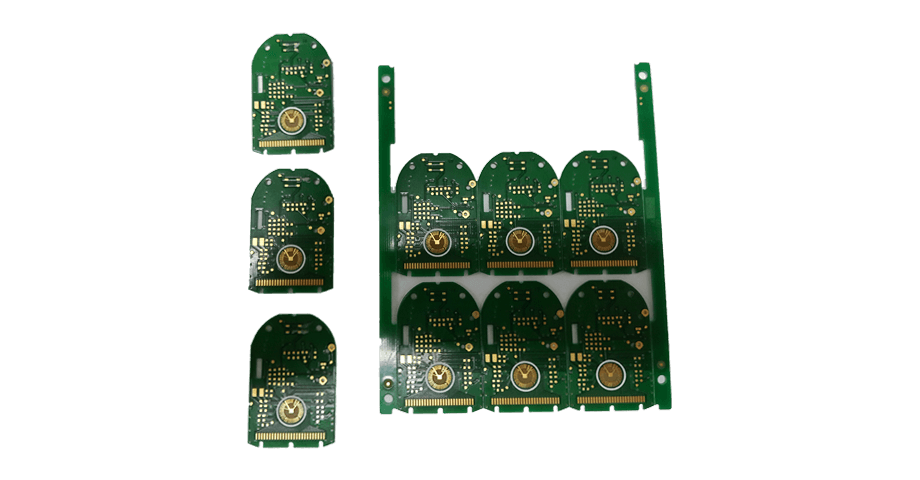

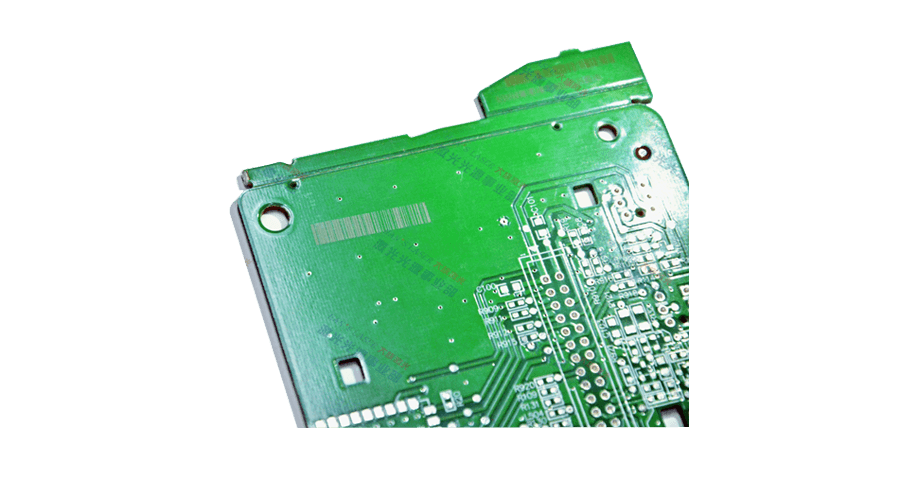

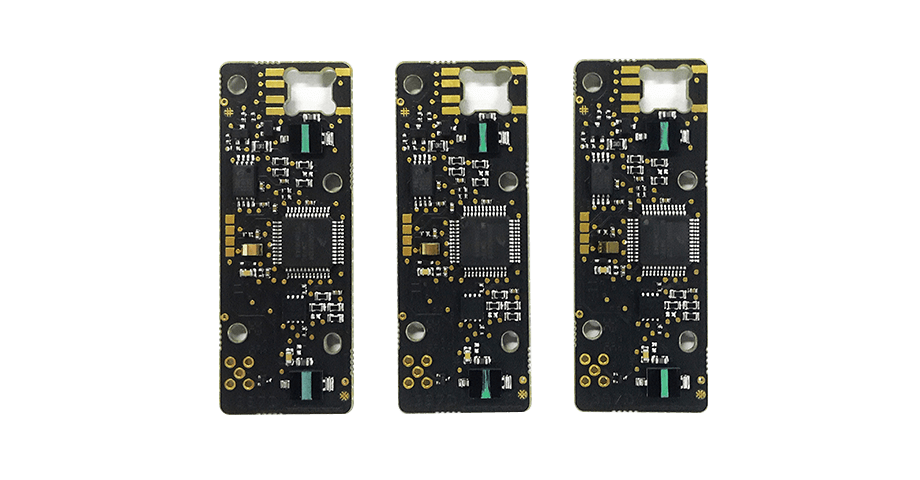

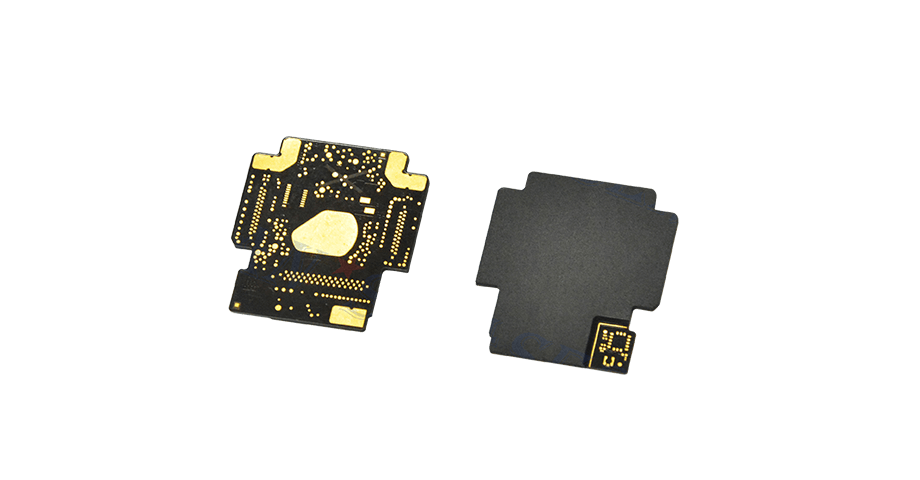

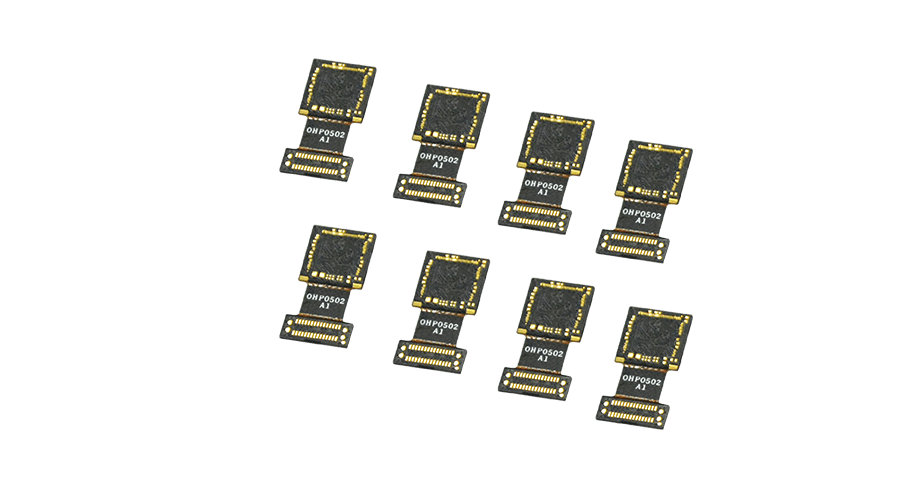

Application and Samples

- Rigid FR4, Flexible printed circuit boards, PCBA

- Glass substrates

- Ceramic

Technical Specs

| Laser Type | UV Laser |

| Wavelength | 355 nm |

| Min Beam Diameter | < 10 µm |

| Beam Quality M2 | < 1.2 |

| Pulse Frequency | 10 - 200 kHz |

| Output Power | 15/20 Watts |

| Repetition Accuracy | 3 μm |

| Cooling System | Water-cooled |

| Fθ Marking Field Size | 1.96" x 1.96"(50mm x 50mm) |

| X, Y travel Distance | 15.74" x 11.81"(400mm x 300 mm) |

| Laser Safety Level | Class I |

| Electrical Connection | 110 - 230 V (± 10%) 16 A,50/60 Hz |

| Power Consumed | 6 Kw |

| Dimensions | 41.73" x 39.37" x 72.83" (1060mm x 1000mm x 1850mm) |

| Warranty Coverage(Parts & Labor) | 1-year |

| Laser Safety Compliance | FDA(CDRH) |

| Running Temperature | 15℃-35℃ / 59°-95°F |

Options and Accessories

ABOUT HAN'S LASER CORPORATION

Han's Laser Corporation is a wholly-owned subsidiary of Han's Laser Technology Group, a global industrial laser technology leader.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

We are committed to providing our customers with the latest industrial laser machine technology to suit their particular needs better.

Headquartered in the U.S., employed by knowledgeable, trained personnel. Han's Laser is transforming the industry with our state-of-the-art machines.

Han's Laser Technology Industry Group Co., Ltd, a public company established in 1996, has become the Chinese national laser industry's flagship and one of the world's most famous laser equipment manufacturers. Han's Laser went public in Shenzhen Stock Exchange Market in 2004. And as of today, its market value reaches more than 7 Billion USD.

CLIENTS